Injection Molding

Expanded PET Preform Molding Machine Line

Netstal expands its PET-LINE series introducing a 306 metric ton (m.t.) version with side entry at drinktec.

Read MoreSodick IMM Plustech Adds Showroom in California

Sodick IMM Plustech will host an open house on July 19-20 to celebrate the opening of a new parts and product showroom in Yorba Linda, Calif.

Read MoreCalculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

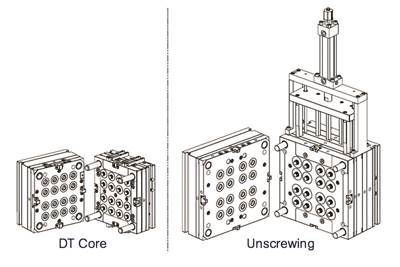

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreSpecialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.

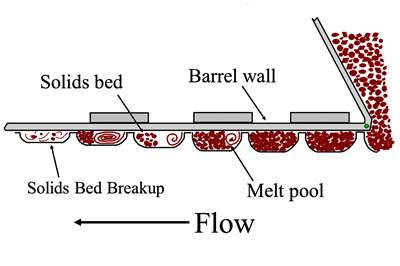

WatchImprove Quality & Productivity With Advanced Screw Design

Most molders are still running with screw designs that haven’t changed much in 30 years. But they don’t need to.

Read MoreOnline Visibility of Machine Availability

Arburg’s Ready2Go app lets European users see available injection molding machines, which the company says can be delivered in three to four weeks.

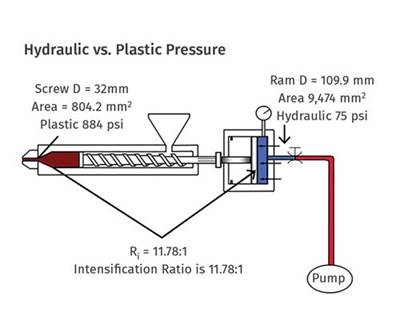

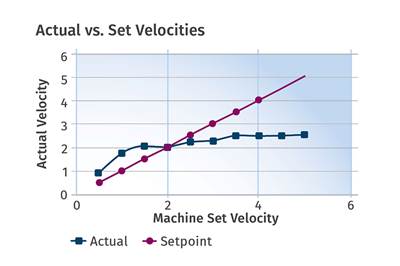

Read MoreStop Controlling Your Injection Molding Process with Machine-Only Settings

Monitor and record process outputs instead of the machine setpoints to ensure a validated process regardless of any machine deterioration, viscosity changes or other alterations.

Read MoreHow to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

Read More