Injection Molding

Grand Traverse Plastics Announces Expansion

The Northern Michigan automotive injection molder is investing $11.5 million in support of a new electric-vehicle (EV) program.

Read MoreMinnesota Rubber and Plastics to Build Innovation Center

The medical focused injection molder says the new 9000-ft2 innovation center will give its customers a design-prototype-build-test outlet for the creation of new devices and components.

Read MoreFakuma: Arburg to Stress Digitalization and Sustainability

Arburg’s arburgXworld and arburgGREENworld programs will be highlighted at the fair, including new digital services and features; digital watermarks for end-of-life part sorting, molding biobased plastics and more.

Read MoreFakuma: Boy Brings Eight Machines to Friedrichshafen

Neustadt-Fernthal, Germany based Boy will have four machines at its Fakuma stand this October, with an additional four presses running at partner booths.

Read MoreFakuma: Larger, Modular, Multicomponent Injection Molding Line

Arburg introduces the Allrounder More at Fakuma, promising more space for bigger molds and longer ejector strokes plus flexible positioning of injection units.

Read MoreFakuma: Robot Makes Safe, Early Starts; Optimizes Path Planning

Engel is expanding its range of smart assistance systems at Fakuma 2021 adding the new iQ motion control to its viper series linear robots.

Read MoreFakuma: Wittmann Battenfeld to Launch Machine Line at Friedrichshafen Fair

In addition to introducing its new SmartPlus line of servo-hydraulic injection molding machines, Wittmann Battenfeld will feature multiple machines at its booth and stream video of other cells from its labs.

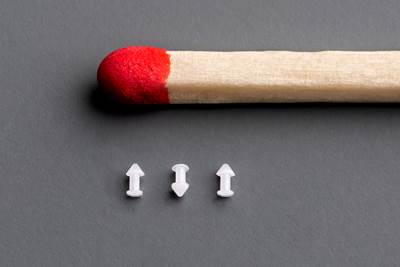

Read MoreMicro-Injection Molding LSR: Exploring the Limits of What’s Possible

Molding delicate LSR parts weighing 0.5 mg in 32 cavities requires high precision and repeatability in molding and careful post-mold handling. Here’s a look at the challenges of micro-molding with LSR and what makes it different from thermoplastic micro-molding.

Read MoreTriMas Building Greenfield Molding Site in Ohio

Rieke, part of the company’s packaging group, is currently building a 230,000-ft2 facility in New Albany that is expected to begin production in the second quarter of 2022.

Read MoreBuilding a Better Mousetrap-Manufacturing Process

Increased demand for its products, which include rodent traps and more, lead Bell Labs to Wittmann Battenfeld to help it better automate its molding processes.

Read More