Injection Molding

Low-Pressure Injection Process Facilitates ‘Green Molding’

Besides speed and quality advantages, the low-pressure iMFLUX process is said to enhance sustainability—easing use of recycled and biobased materials, saving energy, reducing scrap, and adding lightweighting potential. See what molders say about these “green” benefits.

Read MoreNovation Industries Ramps Up Unprecedented Production Volume for Face Masks

Molding parts every 18 to 28 seconds, filling a box every minute, and shipping an average three truckloads of product every day—Novation has risen to the coronavirus challenge.

Read MoreBack to the (Re)Grind

Some amount of scrap—generated in startup, shutdown or defective parts—is inevitable. How can you reclaim regrind into new profitable parts?

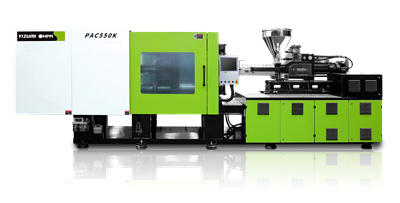

Read MoreInjection Molding: Upper Range of High-Speed Packaging Presses Extended

Yizumi-HPM has expanded its PAC-K series of injection molding machines, adding a fourth model with 610 tons of clamping force.

Read MoreNolato Group Acquires GW Plastics

The Vermont headquartered injection molding, moldmaking and contract manufacturing firm founded in 1955 becomes part of the global, publicly traded Swedish conglomerate.

Read MoreFakuma Show Goes On (Digitally) for Wittmann Battenfeld

Self-contained inline scrap integration; medical, LSR, and packaging Cells; an MES Upgrade and more to be introduced virtually.

Read MoreFive Questions to Ask Before Instrumenting a Mold

There are plenty of good reasons for putting sensors in a mold—but what is most important for your application? Answer that first, before considering what type of sensor to use and where to locate it.

Read MoreMetro Mold & Design Adds Four Injection Molding Machines

Minnesota based injection molder and blow molder invested a total of $4 million in equipment, including four Engel injection molding machines and Ilsemann Automation technology.

Read MoreAdditive Manufacturing and Injection Molding Increasingly Complementary in Covid-19 Crisis

The coronavirus crisis has often simultaneously required the speed of additive manufacturing and the scale of injection molding.

Read MoreInjection Molding: Miniature Force Sensor

New crystal at the heart of Kistler’s miniature piezoelectric force sensor.

Read More