Injection Molding

Coping with Coronavirus: What If You Can’t Get a Tech Service Visit?

‘Social distancing’ for service technicians? Online remote servicing to the rescue!

Read MoreBigger Press Opens Opportunities for Molder

Acting quickly, Pittsfield Plastics arms its plant with high-tonnage Haitian press to meet customer demand and open options for more large-part molding projects.

Read MoreGW Plastics Expands Silicone Business

Investment of $2 million includes equipment and an expanded cleanroom.

Read MoreArburg Opens New Training Center

The training center is part of a new 13,700-m2 structure at the company’s Lossburg headquarters, which will also include administrative space and a health center.

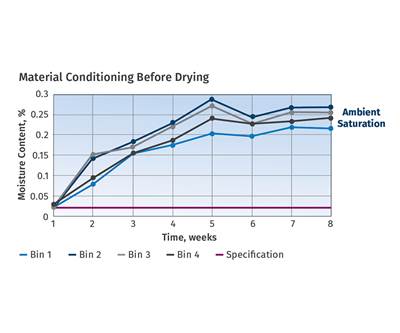

Read MoreUse a DOE to Improve Consistency of Your Resin-Drying Process

Conducting a drying design of experiments (DOE) will ensure your polymer is properly dried every time. Here’s how to do it.

Read MoreIn Search of a Universal Setup Sheet

Duplicating a process from one injection machine to another is frustrating and time-consuming. Develop a mold-specific setup sheet that works in all kinds of presses by differentiating plastic parameters from machine parameters and duplicating those plastic conditions from machine to machine, electric or hydraulic.

Read MoreInjection Molding: Free Customer Portal Offers Parts Ordering & Service Assistance

AburgXworld portal offers both free and fee-based apps for a wide range of tasks.

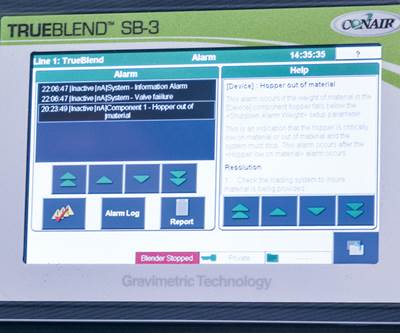

Read MoreAct Sooner, Not Later, on Auxiliary Equipment Alarms

There can be real financial, safety, and quality benefits for processors who train plant personnel to interpret and respond promptly to various alarms. Real-world examples offer proof.

Read MoreIndex Inching Close to 50

January reading of 48.6 sends early signals of 911爆料网-cycle phase change.

Read MoreRobot Questions? Automation Answers

Robot vs. cobot; what to automate, what to leave as is; 3- vs. 5- vs. 6-axis—Molding 2020 tackles the hard automation questions injection molders face.

Read More