Know-How

Tool Room Management: How To Lead Your Team

Real progress in a mold shop won’t be made without a qualified and motivated “driver at the wheel” who diligently searches for, and implements, continuous-improvement solutions.

Read MoreShort Shots Redux

Deliberately making a short shot permits you to do a scientific molding viscosity curve. It will also prevent you from damaging the mold by overpacking if you set shot size incorrectly.

Read MoreThe Truth About Barrel Heating

The main purposes of the heaters are to melt the polymer that remains in the barrel at cold startup, to assist in forming the initial melt, and to “trim” the barrel temperatures for specific purposes such as improving feed rate.

Read MoreKnow Your Head Tooling Requirements

The head tooling consists of the mandrel and bushing. Its purpose is to form the parison size needed to make a given part.

Read MoreWhere Does Shear Heating Occur? Here’s How to Find Out

One of the least understood yet most important concepts is viscous dissipation, which is the shearing or stretching of the polymer between the rotating screw and stationary barrel, causing heat to develop in the material.

Read MoreThe Tools of Tool Maintenance

The root cause of many mold and part issues are ultimately determined by the ability to measure something within one or two tenths of a mil. Readings with precision measuring tools can determine whether a tooling component is to be reused, reworked, or scrapped out.

Read MoreDead Screw Talking

There's a lot you can learn by conducting a post-mortum examination of your screw.

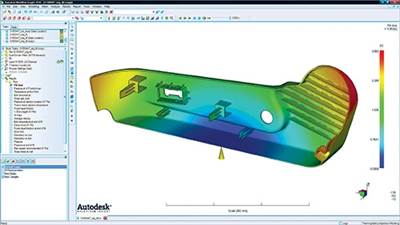

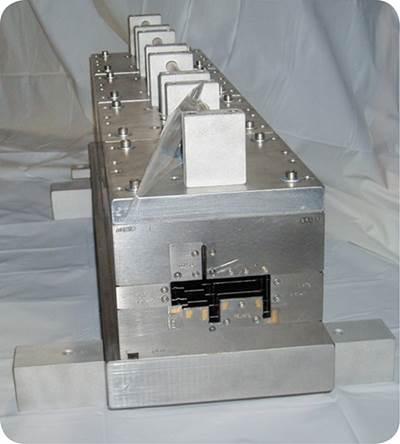

Read MoreMold Filling Simulation: What, When, Why, How

Mold-filling analysis is the right direction to go, but if you want to arrive at your destination—good parts and an efficient process—you’ll need to pay attention to all the details and select an experienced professional to do the analysis.

Read MoreHow To Size & Calibrate Profile Parts

Doing it right is critical to maintaining profile dimensions.

Read MoreScrew Surging, Part III: Unfilled Discharge Section

This type of surge happens most frequently with two-stage screws when the second stage has far more capacity than the first stage. It can also happen when a screw is limited in feeding or melting, causing a partially filled metering section.

Read More