Tooling

Tooling: Why Ejector Pins Break and How to Prevent It, Part 3

Here we focus on forces, friction, surface finish, and lubrication.

Read MoreInjection Molding: Sliding vs. Locking Ring—Which Non-Return Valve Is Right for You?

The locking-ring style appears to dominate the market, as most believe it makes a make a better seal and leaks less. But is this really so?

Read MoreTooling: Why Ejector Pins Break And How to Prevent It, Part 2

Here’s the when and how to reduce the unsupported length of pins.

Read MoreCollaborative Mold Design Experiment Based on Clariant's Color Trends

Mold texture specialist and Clariant investigate interaction of social trends, color and textures.

Read MoreHot Runners: Single Valve Gate System Features Compact Profile

By doubling as a locating ring and housing all the mechanics internally, a new valve-gate system greatly reduces mold-height requirements.

Read MoreHot Runners: Pre-Assembled, Pre-Wired Hot Runners Offer Installation Without Pre-heating

Hot runner system’s nozzles promise a consistent thermal profile and wide molding window without the risk of polymer leakage or accidental cold condition starting.

Read MoreTooling: Why Ejector Pins Break...and How to Prevent It, Part 1

In part one of this four-part series, we focus on the molding machine and the ejection system as culprits.

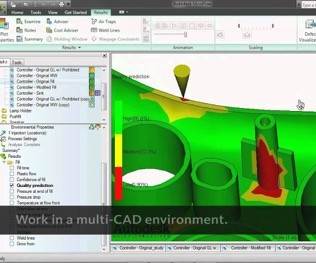

Read MoreNew Webinar: How to Use Simulation to Reduce Material and Part Cost

Register for this free webinar on reducing downstream risk through injection molding simulation software. (Sponsored Content)

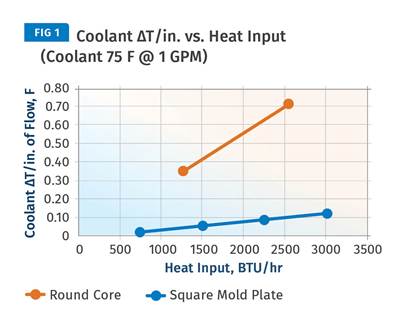

Read MoreAn Engineering Approach to Mold-Cooling Circuit Design

The Energy Density vs. ΔT/in. relationship is an important step forward in pursuit of a science-based approach to cooling-circuit design. Here’s why.

Read MoreTooling: Clamp Pressure & Cavity Land Area, Part 2

What you need to know to prevent flashing and mold damage.

Read More