Articles

Leading Cast Film Processor Adding Blown Film Capacity

Malpack adds two multilayer blown film lines for agricultural, stretch hood and shrink films.

Read MoreWhat's Restricting My Output Rate?

In a single-screw extruder, it could be an improperly designed barrier flighted entry section. Here’s why.

Read MoreMaterials Suppliers Team on PFAS-Free Solutions

Baerlocher PFAS-fee process aid passes muster in resin manufacturer’s testing on production-sized blown film line.

Read MoreDesign Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read MoreImportant Factors and Approaches to Estimating Residence Time in Injection Molding

Residence time can have a dramatic impact on part quality and production efficiency but determining its value can be tricky. Use these methods and formulas to accurately measure residence time and enable it to inform everything from scheduling jobs to optimizing a process.

Read MoreResearch Deems Bioplastics, Wood Pulp a Sustainable, Economic Alternative for Rigid Packaging

Farrel Pomini and FPInnovations produce biodegradable compound for molding, extrusion and thermoforming applications.

Read MoreDirect Solar Heating for Rotational Molding Enables Feedback Control and Rapid Deployment

Light Manufacturing offers rotomolding factory in a box, with no utilities needed.

Read MoreWhat Plastics Technology's Content Gate Means for Its Web Visitors

Plastics Technology has installed a “content gate” on its premium articles online. What does that mean and why should you care?

Read MoreEvery Link in the Chain

From accumulators to X-ray fluorescence analyzers, the 2024 Plastics Technology Handbook & Buyer’s Guide is the reference source for the plastics processing supply chain.

Read MoreMaking Gains in the Drain Game

AWD blends extrusion and thermoforming technologies with plenty of home-brewed equipment and processes to keep water away from where it isn’t supposed to be.

Read MoreArburg Open House Emphasizes Turnkey Capabilities

Held at the company’s U.S. headquarters in Rocky Hill, Connecticut, the event featured seven exhibits, including systems that were designed, sourced and built in the U.S.

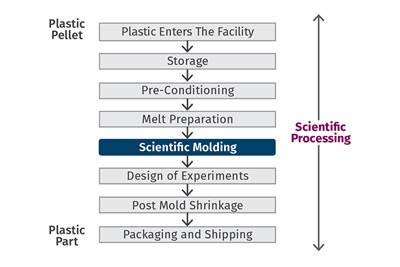

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read More