Blow Molding

Energy Miser: Reducing Compressed-Air Usage

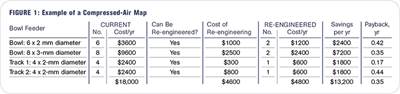

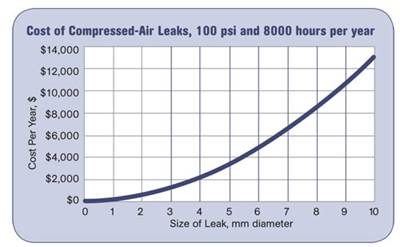

Many manufacturing sites operate on the assumption that compressed air is free. Usage is totally uncontrolled, and open air lines cost real money.

Read MoreNovel Fuel Systems Power Blow Molder’s Growth

Nano technology gives The Plastics Group a leg up on developing fuel systems for non-automotive applications

Read MorePepsi Develops First 100% Biobased PET Bottle

WEB EXCLUSIVE: PepsiCo, Purchase, N.Y., says it has developed the world’s first PET bottle made entirely from plant-based, renewable resources.

Read MoreHow to Manage Multiple Heads in Accumulator Blow Molding

Don’t believe the myth that you can’t successfully run an accumulator-head machine with more than one head.

Read MoreHeinz Ketchup Converts to Biobased Bottle

The sauce is red, but the new bottle is green—i.e., based partly on renewable plant-based feedstocks.

Read MoreMaking a Part for the First Time? Here’s How to Get Going

First time parison programming for a new part can be lengthy and tedious. Here's some advice on making the process a bit easier

Read MoreBonanza of Hot Runners & Controls Introduced at K 2010 Show

At the world’s largest plastics show in Dusseldorf last fall, hot-runner and controller manufacturers introduced a flood of new developments in speed, size, accuracy, and reliability.

Read MoreFoamed PET Bottles for Beer

Now the foam isn’t just on top of the beer, it’s all around it.

Read MoreEnergy Miser: Plug Costly Compressed-Air Leaks

Last month we introduced the idea that compressed-air usage is one of the first places any manufacturer should look to reduce energy cost.

Read More