Blow Molding

ANTEC at NPE: Editors' Picks

One of the unusual features of NPE 2009 in Chicago June 22-24 will be the first-ever concurrent presentation of the SPE ANTEC conference, by far the largest of seven conferences at McCormick Place during the show.

Read MoreNPE 2009 News Flash

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

Read MoreInternal Benchmarking: Setting Targets

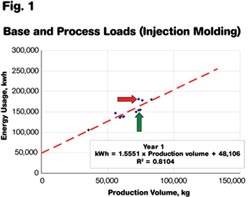

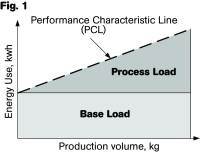

Last month, we discussed how to graph your plant’s “process energy fingerprint.” Now we’ll show you how to make use of that information.

Read MoreKnow Your Plant’s ‘Energy Fingerprint’

It is commonly thought that energy use in plastics processing is fixed and uncontrollable.

Read MoreIntroduction to Energy Management For Plastics Processors

Energy efficiency is one of the “hot” topics of the 21st century and plastics processors around the world are trying to come to terms with it.

Read MoreControl Oxidation of HDPE Parts

For blow molders of HDPE parts, this is an all-too familiar sight at start-up time on Monday morning: The machine is purging leftover material onto the floor.

Read MoreGet a Handle on Stress-Cracking In HDPE Bottles

One of the first applications for blow molded HDPE bottles was the replacement of glass for bleach packaging.

Read MoreCoatings Give Aluminum Molds Cost/Performance Edge Over Steel

New cost-effective technologies are designed to make aluminum an attractive alternative to tool steels in a range of plastics molding processes. One method uses a plasma technique to convert the aluminum surface into a hard, dense, wear-resistant ceramic. Another approach uses electro-deposition to apply a surface coating with high hardness, corrosion resistance, and chemical resistance.

Read MoreCompression Molded PET Preforms Challenge Injection Molding

Lower cost, higher quality and productivity, and the potential for lightweighting beyond anything yet seen are benefits claimed for a new continuous compression molding process for making PET bottle preforms.

Read MoreConair and Husky Jointly Offer PET Systems

WEB EXCLUSIVE The Conair Group, Inc., Cranberry Township, Pa., and Husky Injection Molding Systems Ltd., Bolton, Ont., have agreed to jointly supply complete PET preform manufacturing systems worldwide.

Read More