Blow Molding

Chemical Purging: When and How to Do It Right

Extrusion blow molders are sometimes skeptical of chemical purging compounds (CPCs), and they have a point.

Read MoreGlobal Competition - High Shipping Costs Give U.S. Blow Molders an Edge

When it comes to foreign competition, blow molders feel relatively invulnerable in their biggest market–bottles.

Read MoreEliminate Problems with Container Handles

Extrusion blow molding a container with a handle may sound easy.

Read MoreNPE 2006 News Wrap-Up: Blow Molding

Among new blow molding developments at the show was an innovative coextrusion system for the growing small-engine fuel tank market.

Read MoreWhat to See at NPE 2006: Blow Molding

Show-goers will see a range of new blow molding equipment that offers higher speeds, more cavitation, and faster changeovers.

Read MoreNPE News Preview: Blow Molding--Higher Speeds, More Cavities, Faster Changeovers

Improving productivity while minimizing capital cost and floorspace will be central themes of blow molding exhibits at NPE 2006.

Read MoreSmall Fuel Tanks: New Emissions Rules Spur Hunt for Barrier Solutions

Coex blow molding has the inside track, but makers of small gas tanks and jerry cans are also looking at fluorination and other monolayer systems. Rotomolders, too, are considering multilayer alternatives.

Read MoreSmart Handling of Regrind Can Improve Your Bottom Line

Dealing effectively with regrind has been a tough challenge for most blow molders ever since the process was invented.

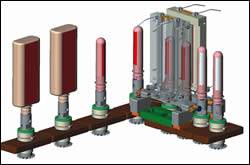

Read MoreBlade System Puts Ribs Into Structural Blow Molded Parts

A novel blow molding process incorporates movable blades within the tool to create a ribbed structure for load-bearing automotive parts.

Read MoreNew Association for IML, IMD

Last month saw the official start-up of the In-Mold Decorating Association (IMDA), an association of molders, printers, materials suppliers, and equipment manufacturers involved in in-mold labeling and decorating (IML and IMD) for any plastics process.

Read More