Extrusion Know How

The Scale-Up Conundrum

There are many methods used to determine scale-up based on output, but most designers do not scale the melting requirement along with the output.

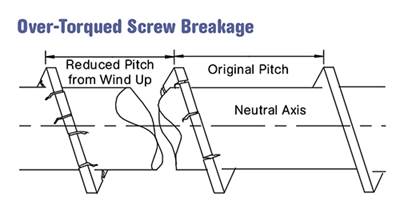

Read MoreUnderstanding Screw Breakage

You might think you're over-torquing the screw, but more often than not bending is the reason.

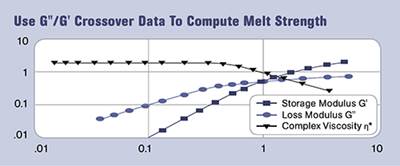

Read MoreExtrusion: Where's the Data? The Importance of Melt Strength in Extrusion

All extrusion processes depend to some degree on the melt strength of the polymer, and this property is generally a no-show on data sheets.

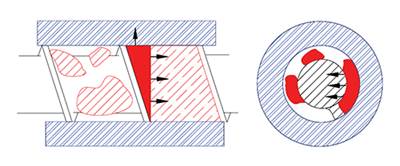

Read MoreThe Cause of Catastrophic Screw Wear

Erratic feeding can be the culprit. This is not uncommon when dealing with recycled material.

Read MoreThe Limits Of Compression Ratio

Don't rely just on this value during the screw design process.

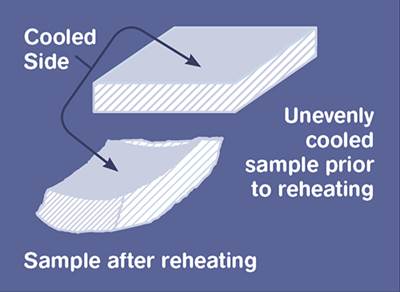

Read MoreCooling Tips for Crystalline Polymers

If a little cooling is good, is a lot of cooling better?

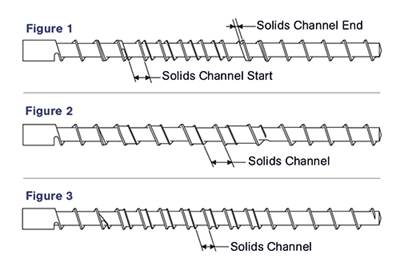

Read MoreThe Evolving Barrier Screw

There has been a gradual transition from the earlier Maillefer designs used in Europe to the Dray/Lawrence design using the parallel barrier design with an increased helix angle to accommodate wider channels.

Read MoreWhy I Still Like Analog Meters

They may not look as slick as their digital cousins, but I find them more helpful in identifying and troubleshooting extrusion problems.

Read MoreScrew Design Is a Matter of Balance

In order to achieve a balance between feeding, melting, and pumping it鈥檚 necessary to use proven calculations and/or tested empirical data in the design of each section.

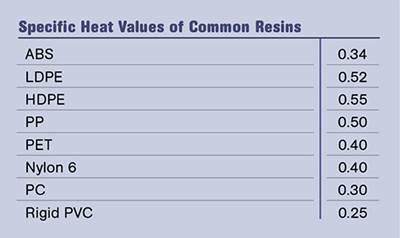

Read MoreWhat Output Should You Expect?

You can get a rough estimate of the potential output if you know the drive horsepower of your machine and the thermal characteristics of one of the materials you鈥檒l be running.

Read More