Extrusion Know How

New Frontier for Single Screw R&D: Mixing & Melting by Extensional Shear

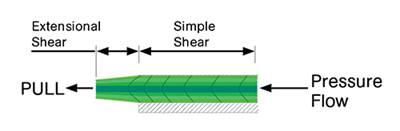

Extensional shear generally has been associated only with twin-screw extruders. However, I am now convinced it can be done with a single moving force (screw) by changing the geometry of the flow field perpendicular to the direction of flow.

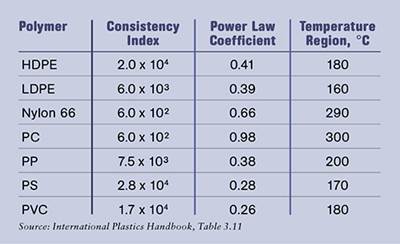

Read MoreThe Power-Law Coefficient

By referring to the power-law coefficient, the effect of barrel override in the metering section of many screws can be explained and anticipated.

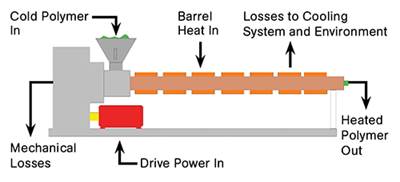

Read MoreMission (Nearly) Impossible: Estimating Extrusion Melt Temperature

Extrusion processors often ask screw designers to estimate the output and melt temperature of a new design in the works. Projected output of a new screw can usually be estimated fairly accurately. Melt-temperature estimate, however, is another story

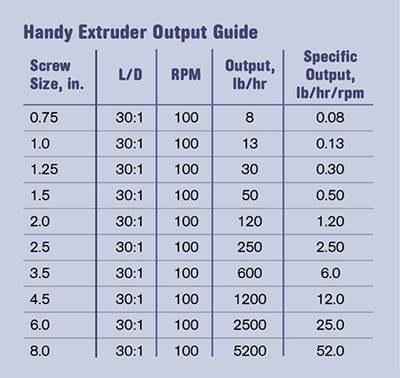

Read MoreGet Smarter on Extruder Sizes

Processors tend to recommend a much larger extruder than what鈥檚 really necessary for the job and the capabilities of the downstream equipment.

Read MoreWhat’s the Deal With High-Speed Extruders?

If we are talking about extruder screw speed, how about 1800 rpm? That鈥檚 how fast some extruders are running today.

Read MoreWater, Oil, Air, or None?

There is no one 'best' barrel cooling medium, but there seems to be a shift in the industry toward air cooling.

Read MoreWell, It Worked on Brand X

You need to give your designer a lot more data than that to make sure you get a screw that's right for you.

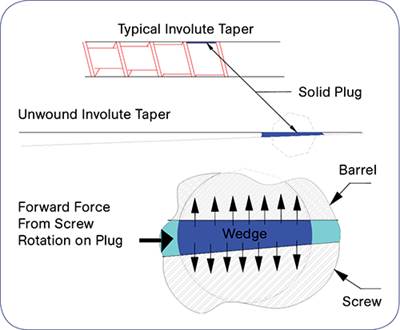

Read More‘Wedging’ Can Cause Severe Screw Wear

In a column I wrote for the July 2011 issue, I discussed the value of conducting “forensic” examination of worn screws when they are removed for clues to design flaws.

Read More