Injection Molding

New Report Details Aging of Manufacturing Workforce

Study from Manufacturing Institute also reveals best practices by companies that are meeting the challenge head on.

Read MorePart 1: The Basics of Tapered Interlocks

Various types of interlocks are available to molders. Here, we discuss the oldest and most common types of interlocks—those with a tapered or angular shutoff.

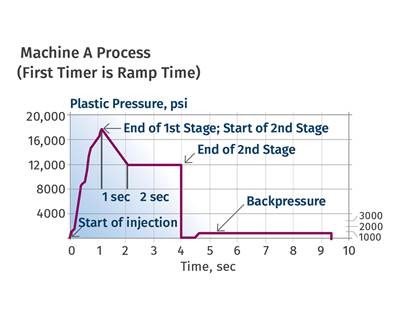

Read MoreGraphing Injection Pressure: What Should Pack & Hold Curves Show?

Are you sure your press is doing what you want? Visit your controller often to ensure your machines plot the pressure vs. time graph for all your processes. Here let’s focus on pack and hold.

Read MoreSpeed and Flexibility Help Molder, Moldmaker Fill a Niche in Product Development

Quotes in hours, parts and molds in days—Xcentric Mold & Engineering brings prototype speed to production molding and moldmaking.

Read MoreMolder’s Philosophy of ‘Giving Back’ Helps Attract New Employees

R&D Plastics participates in numerous programs to further plastics education with local universities and high schools. This effort breeds good community relations and helps attract new employees.

Read MoreRJG Helps Bring Molding Training to Nebraska College

Central Community College (CCC) to embed RJG education into curriculum when new training lab is completed in the beginning of 2020.

Read MoreUsing Decompression to Your Advantage—Your Questions Answered

Since the article on decompression has been published, I have received a few questions that I wanted to share with everyone.

Read MoreInvasion of the Giant Cleanrooms!

Fed by growing demand for medical molding, cleanrooms keep getting bigger and bigger.

Read MoreWho’s Doing Research to Advance the Plastics Industry?

Machinery suppliers are taking the lead in plastics R&D. Engel offers one example.

Read MoreHow to Mold This ‘Impossible’ Part

New low-pressure injection molding process “breaks the rules” and solves difficult molding problems.

Read More