Injection Molding

Understanding—and Using—Decompression to Your Advantage

Decompression—aka suckback—is a very important setting on an injection molding machine. On today’s machines, molders typically get the option to set decompression before and after screw rotation/recovery. Are they using this feature to their advantage?

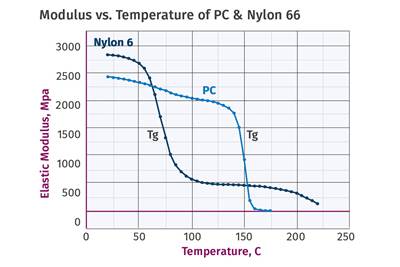

Read MorePART 2: The Importance of Mold Temperature When Processing Polycarbonate

Don’t be afraid to increase mold temperature to improve part quality when making PC parts. Take a look at a few examples here.

Read MoreK 2019 Preview: Injection Molding Goes for the ‘Green’

‘Circular Economy’ joins Industry 4.0 as common themes of injection molding exhibits in Düsseldorf.

Read More‘Circular Economy’ Will Be Unifying Theme at K 2019 Show

Even injection machine suppliers like Engel will talk about ways their technology can support recycling.

Read MoreAutomated 3D Printing at Evco: Composites, Cobots, Email and More

Injection molder Evco has long seen the importance of industrial automation for plastics processing. Its latest automation feat? A cobot-tended cell of 3D printers for manufacturing fixtures and customer products unattended.

Read MoreHillenbrand Inc. to Acquire Milacron Holdings

Milacron joins Coperion, Rotex, and other industrial holdings under the Hillenbrand umbrella.

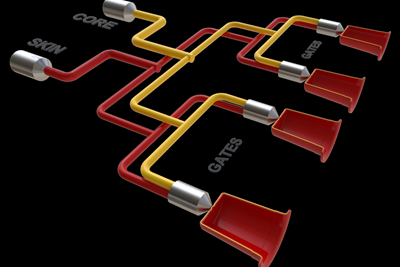

Read MoreA Clearer View of Kortec's Co-injection Technology

Two decades after it was created and five years since it joined up with Milacron and its Mold-Masters brand, Kortec’s co-injection technology can yet provoke misunderstanding among processors.

Read MoreRobert Bosch Venture Capital Invests in Xometry's Manufacturing Marketplace

Xometry's manufacturing services include CNC machining, 3D printing, sheet metal fabrication and injection molding.

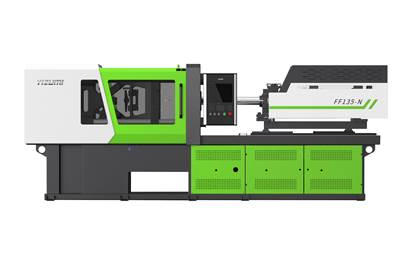

Read MoreInjection Molding: Three New Machine Lines and a Debut in Robots

Yizumi-HPM debuts new all-electric, servohydraulic and two-platen lines, as well as a series of Cartesian robots.

Read More