Injection Molding

NPE 2000 News Wrap-Up: Injection Molding

These two show-goers found what they needed at NPE.

Read MoreNPE Newsfinder: Injection Molding

The abundance of injection molding news at this year’s show is staggering.

Read MoreInjection Molding Close-Up

The latest development in the D-I-M technology is a vertical press with vertical injector, measuring around 5 x 2.7 x 8.8 ft high (with mold open). It allows plenty of room for automation, so it can be integrated into assembly lines, Ettlinger says.

Read MoreNPE Newsfinder: Engineering Thermoplastics

Expect to see numerous entries in automotive engineering thermoplastics at NPE, including a totally new amorphous thermoplastic that is said to provide a breakthrough in color and gloss retention outdoors without painting. Besides exterior body panels, new automotive materials for under-hood, interior, structural, and mechanical parts like gears will also be plentiful.

Read MoreSmall Molder Builds a High-Tech Showplace

How does a small injection molding company position itself to compete with much larger, technically sophisticated rivals?

Read MoreMetal Replacement Accelerates In Under-Hood Parts

Plastics are making new inroads in valve covers and air-intake manifolds on U.S.-built vehicles.

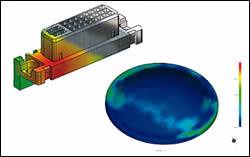

Read MoreThe New Dimension in Mold Simulation

Keep an eye on the increasing prominence of so-called “3D” mold analysis. Two vendors of simulation software from Europe and Asia think it’s the best solution for a big proportion of injection molded parts. Established U.S. suppliers aren’t so sure. In any case, the capabilities of both 3D and standard 2.5D simulation are expanding rapidly.

Read MoreWhat to Do When the Mold Just Won't Fill Right

What should have been a routine injection molding job was plagued with problems right from the start.

Read MoreHow to Optimize Adhesion in Hard-Soft Overmolding

Over the past decade, soft-touch overmolding has radically changed the look, feel, and function of a broad range of consumer products.

Read MorePushing the Limits Of Structural-Web Molding

Four years of development and over $7.5 million have resulted in what is believed to be the largest part ever made by gas-assist injection molding and also the largest ever made by the structural-web process, a variant of gas assist.

Read More