Know-How

Checking and Controlling Nozzle Body Temperature

Temperature control is critical from feedthroat to nozzle tip. Yet despite advances in machinery, this continues to be an issue for molders. Here’s what to do about it.

Read MoreHow to Prevent Nozzle Tip Leaks, Part 1

Instead of learning from your mistakes, stop making them in the first place.

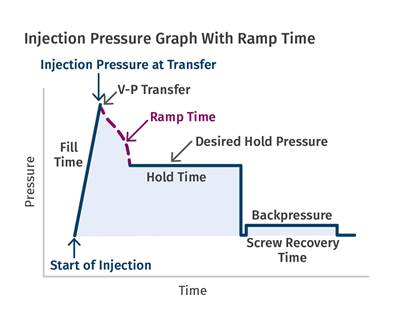

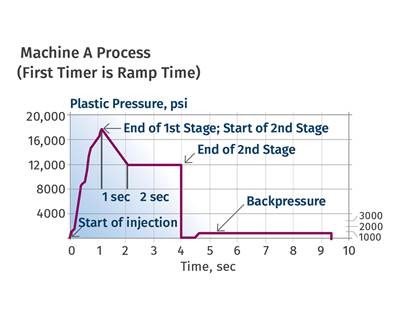

Read MoreV-to-P Ramp Time and Over-Travel

Many injection machines use ramp time to control the transition from injection pressure to hold pressure and reduce over-travel. Do you know how to set yours?

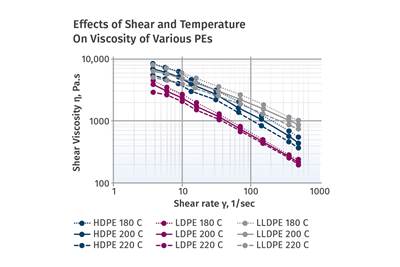

Read MoreUnderstanding Viscosity in Extrusion

Both the power-law coefficient and the consistency index must be considered to calculate viscosity.

Read MorePart 1: The Basics of Tapered Interlocks

Various types of interlocks are available to molders. Here, we discuss the oldest and most common types of interlocks—those with a tapered or angular shutoff.

Read MoreGraphing Injection Pressure: What Should Pack & Hold Curves Show?

Are you sure your press is doing what you want? Visit your controller often to ensure your machines plot the pressure vs. time graph for all your processes. Here let’s focus on pack and hold.

Read MoreUnderstanding—and Using—Decompression to Your Advantage

Decompression—aka suckback—is a very important setting on an injection molding machine. On today’s machines, molders typically get the option to set decompression before and after screw rotation/recovery. Are they using this feature to their advantage?

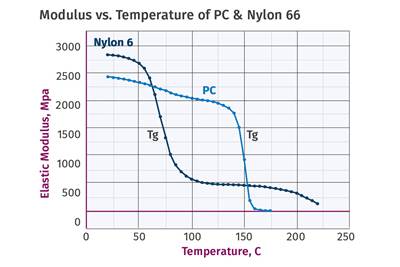

Read MorePART 2: The Importance of Mold Temperature When Processing Polycarbonate

Don’t be afraid to increase mold temperature to improve part quality when making PC parts. Take a look at a few examples here.

Read MorePart 1: The Importance of Mold Temperature When Processing Polycarbonate

An often overlooked factor in optimizing the ductility of PC is the rate at which the polymer is cooled in the mold.

Read MoreHow to Deal With Residual Stress in Molded Parts

Here are design, molding, and fixturing considerations to help you handle this unavoidable issue.

Read More