Know-How

Extrusion Know-How: The Whys & Hows (& Ifs) of Vented Extruders

Vented or two-stage screws only make sense when volatiles must be removed in order to make a satisfactory product.

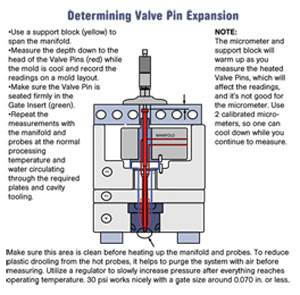

Read MoreTooling Know-How: Troubleshooting Defects--Part II: Hot-Runner Long Gate Vestiges

Last month, we discussed the general issues of an organized and disciplined process of troubleshooting and correcting mold defects.

Read MoreExtrusion Know-How: Proper Alignment Saves Wear & Tear ... or Worse

Is extruder alignment important?

Read MoreInjection Molding Know-How: Drying Tips: A Dozen Details You Should Know

Drying is complicated.

Read MoreTroubleshooting Defects: Part I

Like the three other aspects of a typical mold clean/repair job (disassembly, cleaning, and assembly) there is usually more than one way to skin the cat of troubleshooting and correcting defects.

Read MoreHow Much Horsepower Do You Need?

Most extrusion processors know that in order to boost output you need more power.

Read MoreToday's Lesson: Drying (Part 1)

Listen up, please: This is going to make your life easier.

Read MoreThe Eight Stages of Mold Repair

While the mold was still being disassembled, two “cleaners” began pulling tooling out of plates and putting them into buckets in preparation for a good scrubbing—and I mean a scrubbing.

Read MoreHow to Solve Uneven Clamping

Of the hundreds of variables involved in injection molding, clamping mechanisms and platens often get less attention than they deserve.

Read MoreHow to Determine Maximum Mold Cycle Counts

At my first production meeting with my new employer, I was told, “We want you to establish a preventive maintenance program that is based on maximum cycle counts for all our molds.” Then, before I could launch into an explanation of how best to determine maximum cycle counts, I was hit with the follow-up: “So, how many cycles do you think our molds can safely run before we need to clean them?”Leaving my crystal ball at home and unable to get my x-ray vision working, there was no way to answer this question with any real accuracy.

Read More