Testing

NPE 2006 News Flash

Injection MoldingSimplified Hot Runners Save Time & CostA new lower-cost hot-runner alternative to valve gating is suited to less critical cosmetic applications where users need predictable and reliable gate opening but not sequential gate operation.

Read MoreNanocomposites Do More With Less

For skeptics who may doubt that nanocomposites have yet proven themselves commercially viable materials, last year’s Nanocomposites 2005 Conference in San Francisco presented plenty of evidence that “nanos” are beginning to live up to their promise.

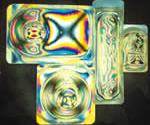

Read MoreStress: Diagnose It Before It Ruins Your Parts

Residual stress is an inherent result of plastics manufacturing processes and occurs when molten polymer is cooled and shaped.

Read MoreNovel Rheometer Tells More About Thermoplastic Processing Behavior

A unique type of oscillating-die rheometer, first unveiled in 1999 for analyzing thermosets and composites, has now been upgraded for testing polyolefins and other thermoplastics.

Read MoreAutomated Assembly Integrates Leak Testing For Lower Cost, Higher Output

Integration of leak testing into a fully automated assembly system proved to be a boon for San Diego-based Gen-Probe, Inc., a pioneer in genetic diagnostics for disease testing.

Read MoreNow It's Here: An Objective Test of Masterbatch Dispersion

There's a new grading system for color concentrates and additive masterbatches.

Read MoreCompounders: Now You Can Monitor Color Inside the Extruder!

If you're compounding colors, there's no need to keep running pellet samples to the lab for periodic quality checks.

Read MoreNew Sources of Help in Coloring Plastics

Two new color services for small to medium-sized firms that lack in-house color-matching and formulating expertise were announced at K 2004.

Read MoreLaser Scanning Pinpoints Shrinkage Problems in Record Time

A faster way to measure part surface dimensions helped injection molder Hy-Ten Plastics to quickly identify and correct geometries in its tooling that spawned problem parts.

Read MoreRheometers: Which Type Is Right for You?

Capillary and torque rheometers are good for simulating processing conditions, troubleshooting, and QC. But dynamic rotational instruments can tell you more about a resin's molecular structure.

Read More