best practices

Injection Molding: New Mold Trial—Will It Run 24/7?

Use this nine-step process to make sure you’ll be making good parts after a successful trial. But even then, be prepared for some hiccups.

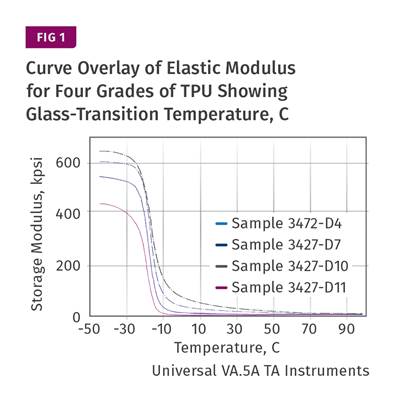

Read MoreMaterials: Cycle Time—Science vs. Rules of Thumb, Part 6

This installment—on elastomers—completes a series, whose theme is to bring more science to the discipline of molding. The overall message: Ask a lot of questions whenever someone posits this or that ‘rule of thumb’ about processing.

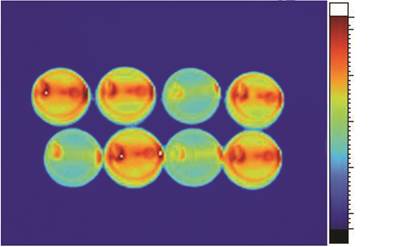

Read MoreAn Inside Look at Turbulent Flow

Years of talk about observing and studying coolant flow in a clear simulated cooling channel finally becomes a reality. Here’s how it all came together, and what it all means.

WatchHow Parkway Makes Stock Jars Into a Custom Business

This family firm distinguishes itself in a commodity market by offering numerous ways to customize its stock products.

Read MoreAdd Automation to Your Lab

Robots are commonplace on the production floor, cutting costs and improving efficiencies for molders and other processors. Now, those same benefits can also be achieved in the lab.

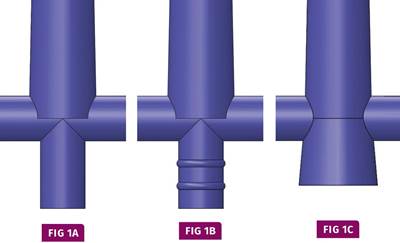

Read MoreTooling: Know the Basics of Sprue-Puller Design

Sprue-puller designs are quite varied, and there are no firm rules to follow. But here are some important cautions and caveats to keep in mind.

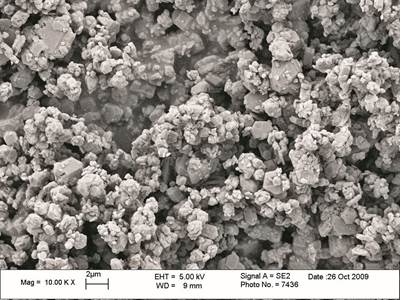

Read MoreExtrusion: The Challenges of Extruding Highly Filled Polymers

These materials require screw changes and modifications in upstream and downstream equipment and operating procedures.

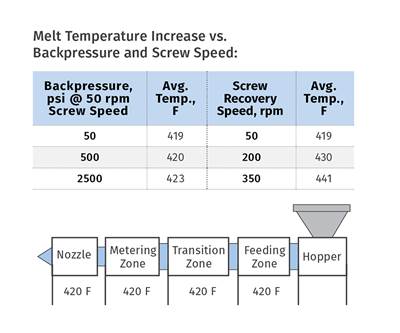

Read MoreInjection Molding: No, Backpressure Does NOT Raise Melt Temperature

It’s a classic confusion between cause and effect. Melt temperature rises when screw speed is increased. Check out this data.

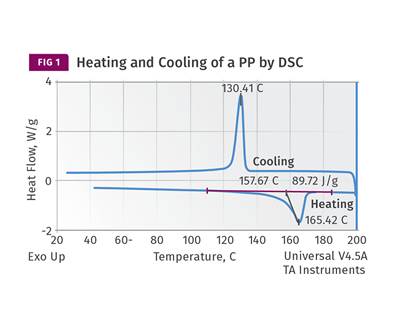

Read MoreMaterials: Cycle Time: Science vs. Rules of Thumb—Part 5

Let’s examine the behavior of semi-crystalline materials that never reach their glass-transition temperature as they cool.

Read MoreMicromolder’s Business Rests On Four Key Technologies

The “four legs” that support Isometric Micro Molding are micro molds, micro injection molding, micro automation, and CT scanning.

Read More