best practices

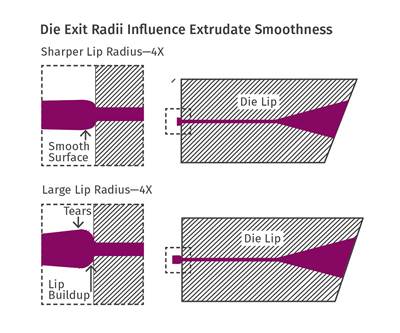

Sharper Dies Make for Smoother Extrusions

Dies that have a radius at the exit will result in poorer surface finish.

Read MoreClamp Tonnage: More Is Better...Right?

Determining the correct tonnage provides a foundation that must be rock-solid to avoid flash and damage. But applying excessive force can create problems with the part, mold, and machine.

Read MoreCycle Time: Science vs. Rules of Thumb, Part 1

What temperature must the polymer reach so the part can be ejected from the mold? Here, more than for any other variable, ‘rules of thumb’ unfortunately prevail.

Read MoreMolder & Moldmaker Embraces Minimalist Tooling Philosophy

RenyMed’s niche consists of projects where it can offer not only molding, but help in designing and making the unique, compact, modular tools that are a company specialty.

WatchWhat You Need to Know About Drying Specialty Nylons

PPA is being used more frequently by molders for demanding high-heat applications in automotive and other markets. While in the nylon family, it does not dry quite like nylon. Follow these tips.

Read MoreBlock Cavities and Keep Molding

It goes against conventional wisdom, but molding with blocked cavities can be done while maintaining quality with the help of appropriate in-cavity sensors and process-control software.

Read MoreIf Two Arms Are Better Than One, Are Four Better Than Two?

Robots with two main arms have proven useful in applications ranging from stack molds to IML to insert molding and performing a variety of post-mold operations. The concept has evolved to the point that a single robot chassis can have two kick assemblies with one or two arms apiece.

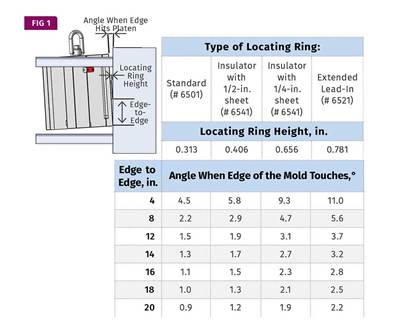

Read MoreLocating Rings, Platen Damage, and the Center of Gravity: Part 3

Selecting the right locating ring and putting it to good use takes careful consideration.

Read MoreSizing the Barrier Gap

Here’s a less complex way to properly size the barrier gap for barrier screws.

Read MoreHow to Duplicate a Process From Press to Press

To adopt the right approach you must distinguish between machine and plastic parameters.

Read More