best practices

How to Use Kinetic Modeling Analysis To Predict Profile Part Failure

Real-world project demonstrates how kinetic modeling can help estimate the shelf life of parts.

Read MoreNew Culture, New Capabilities, New Challenges

Over the last few years, Henkel has not only transformed what its Richmond facility does, but also altered how it operates in terms of culture.

Read MoreTwo-Shot Molding and Tool Design

There are a few variations of the two-shot molding process, and each has implications for tool design.

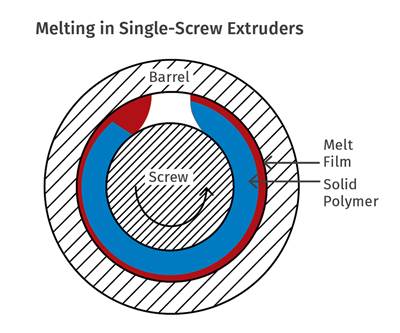

Read MoreExtruding Very High-Flow Polymers

Screw designs not suited to process lower-viscosity materials will result in poor melt quality and lower outputs.

Read MoreFaster Is Not Always Better—Optimize Your Molding Cycle

It is possible for machines to run too fast, so find the sweet spot where maximum output overlaps with good parts.

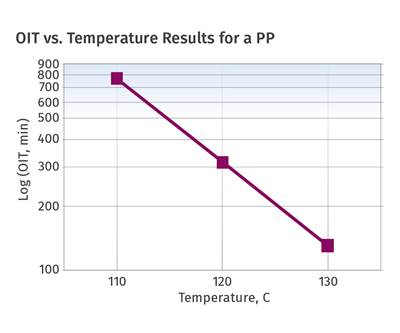

Read MoreThe Importance of Oxidative Stability in Polyolefins, Part 3

Tools and methods for determining oxidative stability can be useful, but even more useful if constructed to yield the information you really need.

Read MoreTool Maintenance: A Molder’s Must-Have

Equipping a toolroom for proper mold maintenance and repair takes more than just the right technology.

Read MoreHow to Troubleshoot Your Feeder to Achieve Optimal Performance

Even the tiniest improvements in compounding feeder accuracy can improve profits. Here’s how to keep your feeding system in the pink.

Read MoreVaulting to Number One Among Heavy-Gauge Thermoformers

For Wilbert Plastic Services, it’s all about bringing together design and engineering to add value for customers.

Read MoreSolving Issues with Gloss

Your problem may be related to tooling, material, processing, or combinations thereof. Here’s how to find the root cause.

Read More