best practices

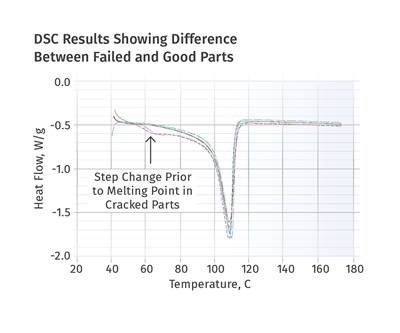

The Need for Generalists: Part 4

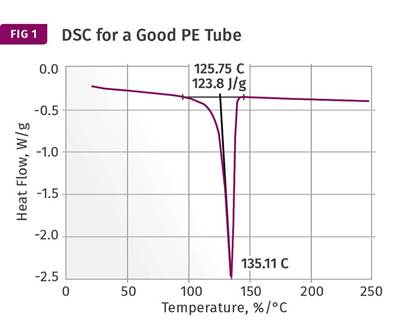

Solving problems generally requires distinguishing good samples from bad ones. But that can become clumsy when one person runs the test while another analyzes the data.

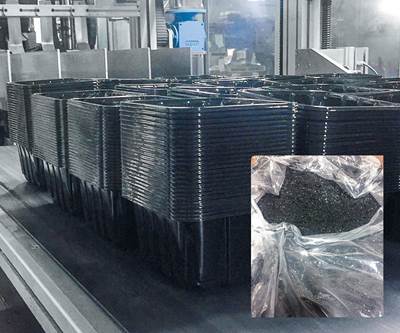

Read MoreHigh-Tech Blow Molding At Agri-Industrial Plastics

This family-owned custom molder stands out in its use of advanced computer and automation tools to claim a niche in large, complex, and multi-layer parts.

Read MoreFormer Has a Full-Blown Focus on Sustainability

Shepherd Thermoforming’s operation has spared millions of PET bottles from death by landfill. It also has taken steps to slash its own energy and water consumption.

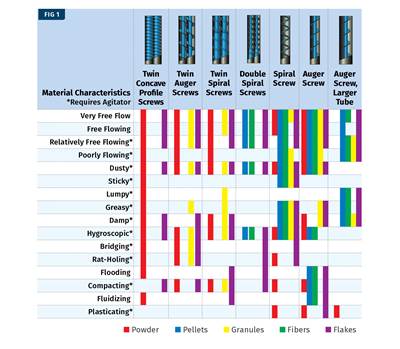

Read MoreOptimize Feeding to Get More Money in Twin-Screw Compounding

Follow these practical examples to improve the feeding efficiency and productivity of your process.

Read MoreUse Molding Simulation To Avoid Surface-Finish Defects

It’s not just for successful mold filling and cooling. Simulation can help predict and overcome cosmetic defects in molded parts.

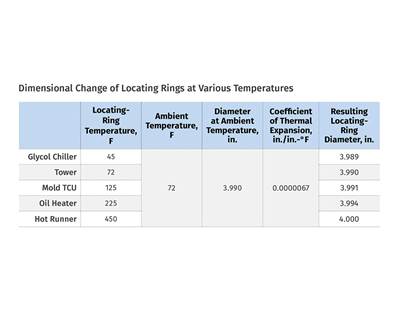

Read MoreLocating Rings and Platen Damage: Part 2

Selecting the right locating ring and putting it to good use takes careful consideration.

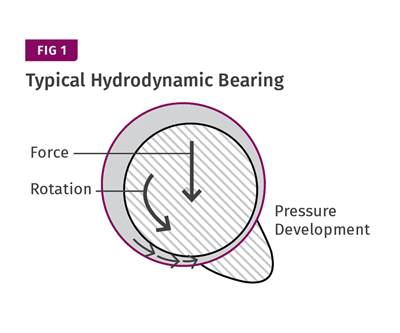

Read MoreHow ‘Hydro Wedges’ Reduce Screw Wear

Using them only in the melting section provides for greater design freedom and negates the impact these devices can have on output and melt temperature.

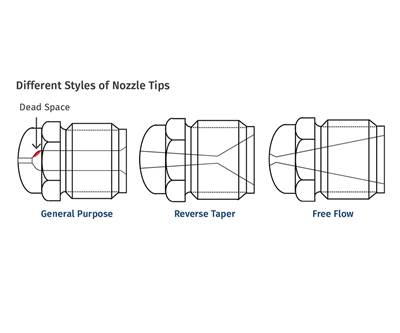

Read MoreHow to Pick, Remove, and Replace a Nozzle Tip

This small component can cause big problems. Here’s my procedure for picking and replacing yours.

Read MoreThe Need for Generalists: Part 3

In failure analysis, there is a tendency to gravitate to a few common test protocols. But this approach can result in a mismatch of techniques to the problem.

Read MoreThree-Pronged Growth Strategy In U.S., China & Mexico

Diversified molder pursues growth on two continents in medical, packaging, and large parts.

Read More