best practices

Blow Molding Challenges Embraced at Metro Mold

“Others mold difficult parts. We mold the impossible.”

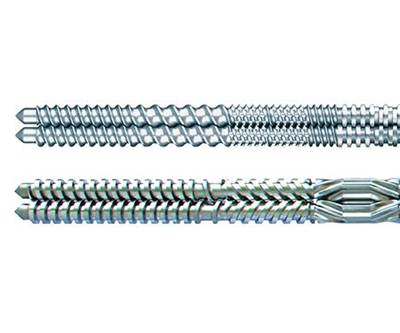

Read MoreGet Better at Swapping Out Your Twin-Screw Elements

Here’s what you need to know to safely and efficiently remove, clean, restage, and reinstall your twin-screw extruder screw set.

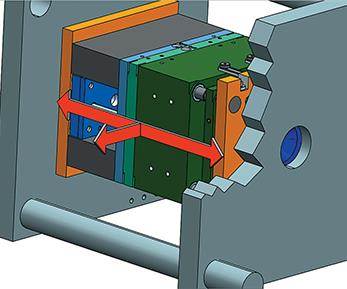

Read MoreTOOLING: The Tool’s Impact On the Molding Process

Flash, venting, cooling, gating, or sticking problems? Better to fix the tool than distort your process.

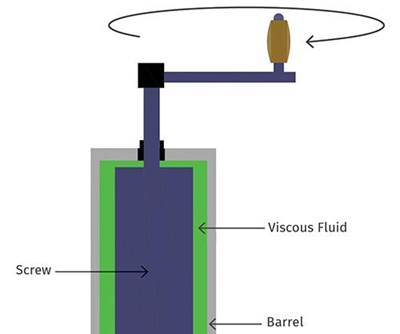

Read MoreEXTRUSION: How Slow Can You Go?

Larger screws designed for high outputs will generate a variety of problems if run too slowly. Here’s why.

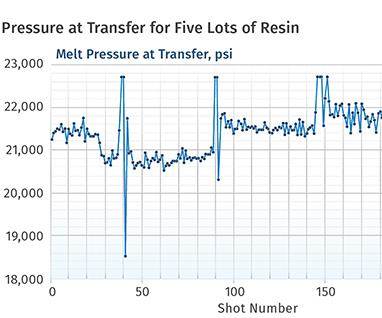

Read MoreINJECTION MOLDING: Processing Nylon…and Other Problems

As moisture content in this and other hygroscopic resins varies, so will your viscosity and process. Here’s how to deal with these issues

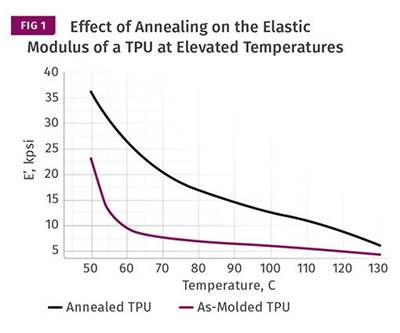

Read MoreMATERIALS: Thermoplastic Urethanes: Why Annealing Makes a Big Difference

Under the right conditions, annealing can drive TPU performance to a greater level than can be achieved at room temperature.

Read MoreCustom Molder Expands in ‘Leaps of Faith’

Who would embark on an $8.8 million plant expansion without new orders in hand? Someone who knows his customers very well.

Read MoreHot/Cold Injection Molding: Which Approach Is Best for You?

The hot-and-cold molding process gives molders a new tool to achieve top-quality esthetics or to fill challenging thin-wall parts. There are a number of options in heating methods, and this article discusses the ins and outs of each.

Read MoreIs Your Granulator Helping You Maximize Your Profit?

It’s easy to take a scrap granulator for granted. Many people do. But getting the most value out of your production scrap requires both a granulator design and a preventive-maintenance program that are appropriate to the way you use the granulator.

Read MorePut Your Dryers on a Preventive Maintenance Program

No one likes to do them. Many avoid them altogether. But a periodic “PM” program for your dryers pays off in the long run.

Read More