best practices

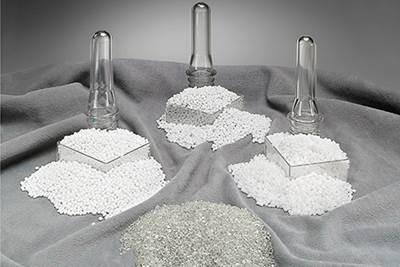

Pellet Production Is a Blast For This Processor

Maxi-Blast opens a plant with brand-new equipment to produce its own pellet blasting media.

Read MoreGet Back to Basics On Water-Cooling Equipment

Neglecting your plant water systems can result in inefficiencies and downtime. Follow these tips when you get new equipment on stream or to maintain what you’re already running.

Read MoreDown in the Valley, Profiles Grow

Valley Extrusions carves niche in tight-tolerance, short-run tubing and profiles.

Read MoreSolve Venting Problems on Twin-Screw Compounding Extruders

Compounds must be free of voids and volatiles or else the material will cause subsequent processing problems. Here’s how to ensure your venting is effective.

Read MoreWhy & When Should You Re-Crystallize PET Scrap?

Whether you’re blow molding PET bottles or extruding APET sheet, you’ll produce amorphous scrap in the process. How you handle it will impact your production costs. Re-crystallizing it will help.

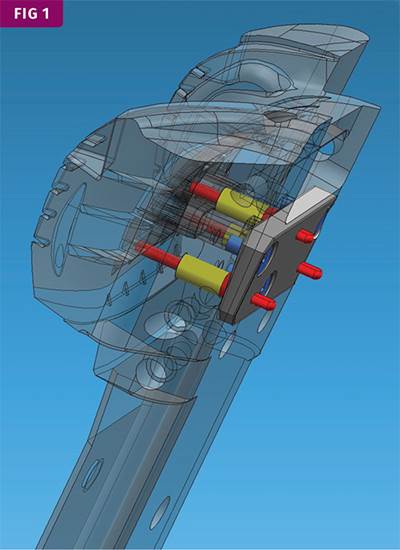

Read MoreTOOLING: Dealing with Lifters--Part 2

This installment delves into more detail on some variables of design and fitting/timing of the lifters, which can cause issues or failures during molding.

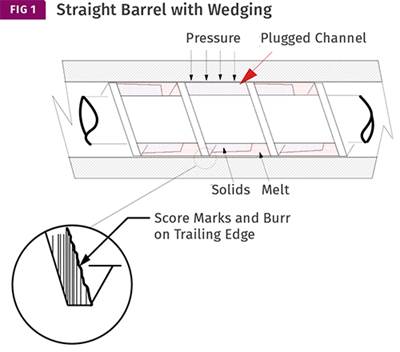

Read MoreEXTRUSION: The Two Main Causes of Screw Wear

Wedging and misalignment are often confused with each other when inspecting a worn screw.

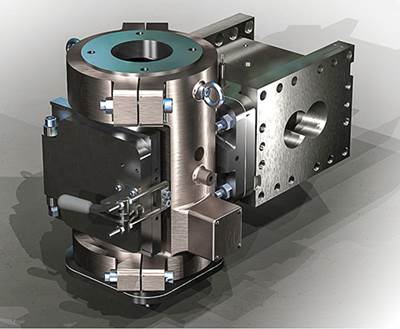

Read MoreINJECTION MOLDING: Gate-Seal Testing Done Right

Follow these 16 steps to perform the experiment and learn what is best for your part and process.

Read MoreSpeed to Market: Pretium Stays Light on Its Feet And Ahead of the Pack

A visit to its largest PET plant illustrates how this versatile blow molder leverages design skills, a can-do attitude, and a high degree of production flexibility to supply custom products in ever-shorter time windows. A new thrust into automation will help pick up the pace.

Read MoreAchieving Zero Waste: Two Processors Prove It’s Possible

Working with an Ohio-based recycler, two film and sheet processors go landfill-free.

Read More