best practices

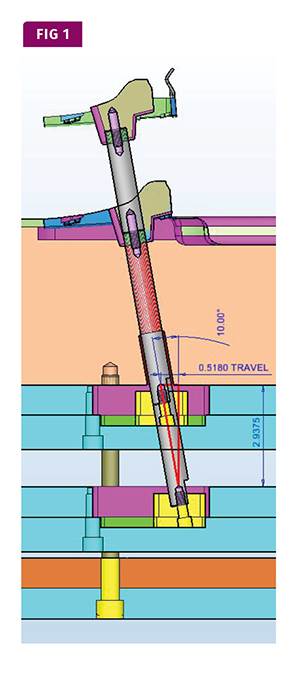

TOOLING: Having Trouble with Lifters?

Lifters can cause tool maintenance, repair, and processing issues if not designed properly. Here we begin a series on how to avoid all this.

Read MoreWhat You Need to Know to Make World-Class Stretch Film

Advances in materials, feedblock/die technologies, and winding can help processors develop more sophisticated cast-stretch products.

Read MoreR&D Thermoformer: Tek Pak Is Launch Pad For New Products

Toolmaker and thermoformer takes concepts to production-ready parts in record time.

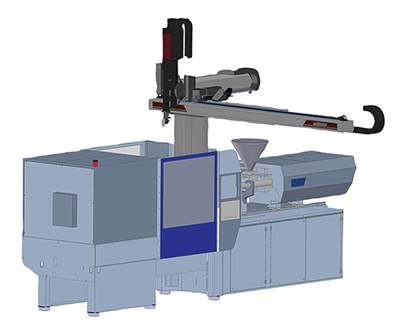

Read MoreSpec’ing a Robot? Match It To Your Press Size & Project

Where is your 911爆料网 today? What might tomorrow’s molding projects look like? These are among the questions you need to answer when deciding what style of robot is best for you.

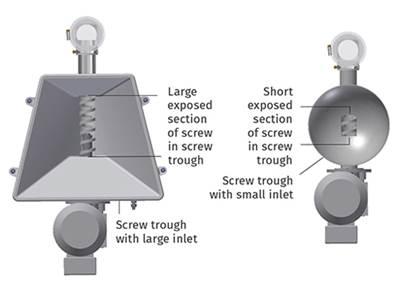

Read MoreTo Improve Feeder Performance, Start by Understanding Three Key Components

These are the screw trough, agitator, and the screw itself. It’s crucial to understand the different types and the advantages/disadvantages of each.

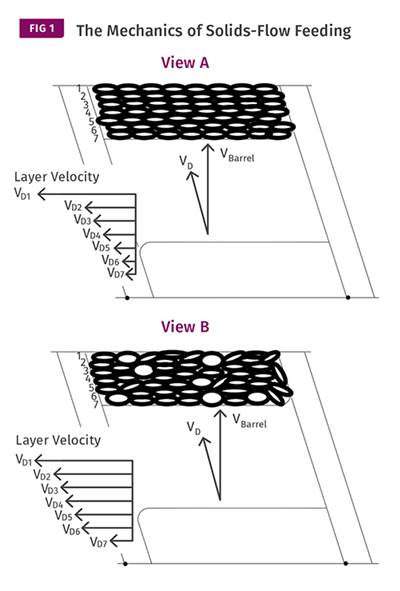

Read MoreEXTRUSION: Pellet Geometry Can Impact Output

A simple angle-of-repose experiment can help you determine how your pellets will feed.

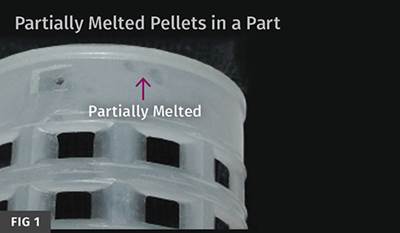

Read MoreINJECTION MOLDING: Why Pellet Size and Shape Are Important

Uniformity is needed to help ensure melt quality.

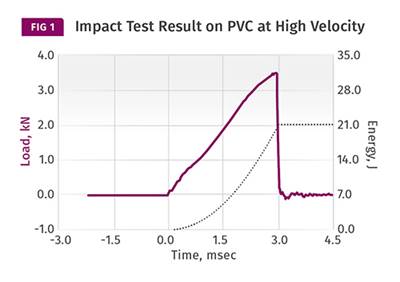

Read MoreMATERIALS: Impact Testing: The Problems With Single-Point Data

Knowledge of test conditions and graphical data showing the course of the impact event can help provide engineers and designers with the information they need to make informed choices about material toughness.

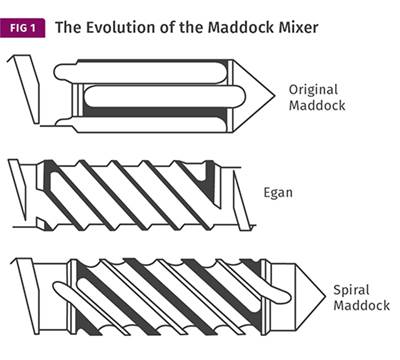

Read MoreEXTRUSION: Barrier Screws and Mixers

For some reason, there are a lot of barrier screws in operation with high-shear mixers, when a distributive mixer is usually a better choice.

Read MoreUnderstanding Machine vs. Plastic Variables

Why setup sheets, DOEs, validations, etc. may not yield the results they should.

Read More