Know-How

Secrets of Quick Part-to-Part Changeovers

Part-to-part changeovers can be fast only with proper advance planning. Here’s what you need to know to convert from sluggish to swift in job changes.

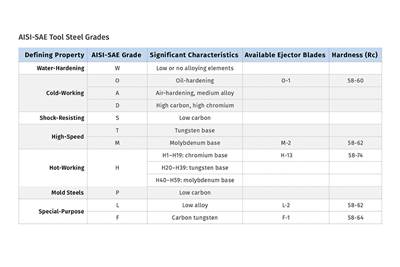

Read MoreWhat You Need to Know About Blade Ejectors: Part 3

Follow these guidelines to prevent premature wear, flash and galling. The focus here is on corner radii.

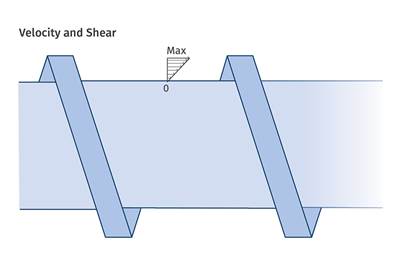

Read MoreUnderstanding the Influence of Screw Geometry on Melting Rate

They are not as closely connected as most processors think. Here’s why.

Read MoreWhat You Need to Know About Blade Ejectors: Part 2

Follow these guidelines to prevent premature wear, flash and galling.

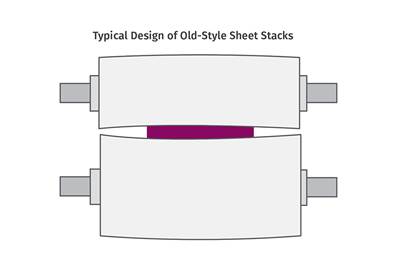

Read MoreUnderstanding Roll Deflection in Sheet Processing

Because of roll deflection, sheet stacks made for PS don’t work nearly as well with PP. One solution is to try a top roll that bends in the opposite direction.

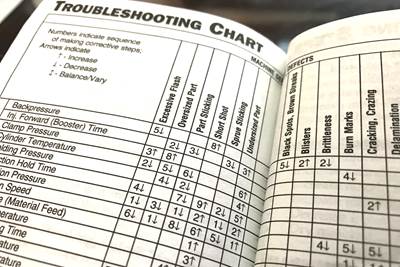

Read MoreApply the Power of a Troubleshooting Checklist to Your Process

Pocket guides provide processors an injection molding “crib sheet,” but in a process with thousands of interactions, applying if-this/then-that logic can’t always get you to a problem’s root cause.

Read MoreTracing the History of Polymeric Materials: Nylon

The story of nylon, the first true engineering thermoplastic.

Read MoreWhat You Need to Know About Blade Ejectors: Part 1

Follow these guidelines to prevent premature wear, flash and galling.

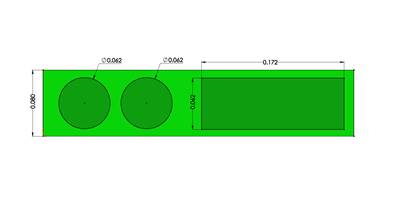

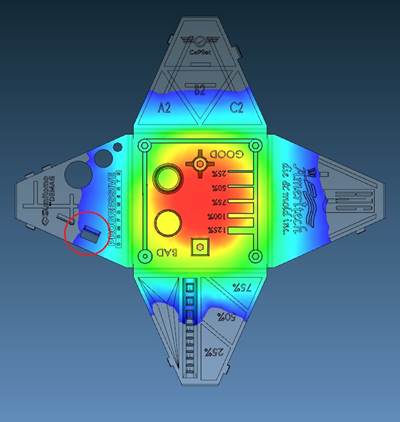

Read MoreThe Difference Between Knit and Meld Lines--and Why It Matters

In many part designs, flow fronts will inevitably be split, but how and where they come back together is hugely important to the molded part’s finished strength.

Read MoreTracing the History of Polymeric Materials: Cellophane

How—and when—cellulose-based chemistry led to the discovery of cellophane.

Read More