Know-How

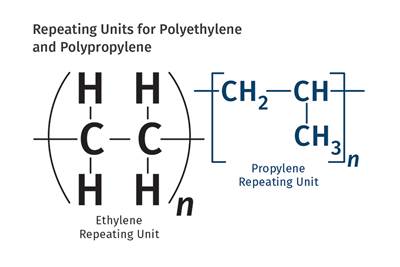

Tracing the History of Polymeric Materials: Commodity Resins

How the ‘Big 4’ commodity materials — PE, PP, PS, PVC — came to be.

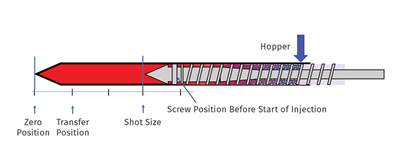

Read MoreConsider the Cushion When Seeking Shot-to-Shot Consistency

Creating and maintaining a consistent cushion is a key step in achieving shot-to-shot consistency. Learn what cushion is and how it affects part quality.

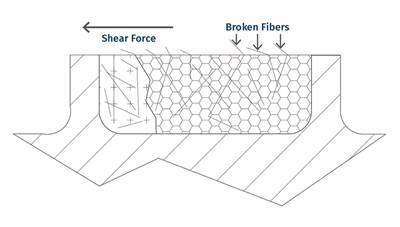

Read MorePut Science into Glass-Fiber Compounding on Single Screws

There are still companies that compound glass fibers on single screws. The process is considered an “art,” but can be made more predictable with attention to screw design, speed and length, as well the choice of mixer.

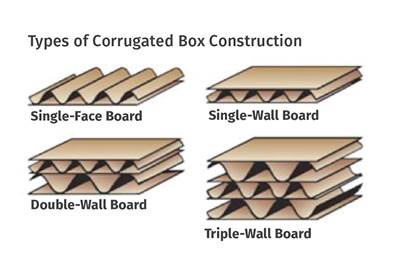

Read MoreGet Better at Quoting Injection Molded Parts: Part 4 of 4

This fourth and final installment focuses on labor, packaging, secondary operations and various assorted details.

Read MoreTracing the History of Polymeric Materials: More on Phenolic

Creation of an invention like phenolic can be traced through a long chain of events and contributors. Here’s the full story.

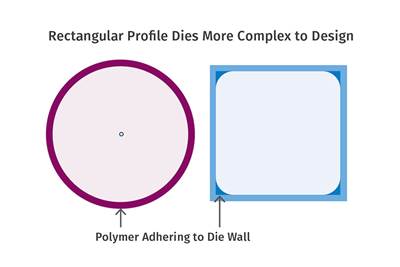

Read MoreExtrusion: Follow These Tips to Get Profile Die Design Just Right

Calculating polymer flow is fairly straightforward when designing a die for a simple round profile, but as the shapes get more complicated these calculations can get extremely challenging. Here’s what you need to consider.

Read MoreTracing the History of Polymeric Materials: Phenolics

In this installment we discuss the discovery of Bakelite, the first truly synthetic polymer, known today as phenolic.

Read MoreGet Better at Quoting Injection Molded Parts: Part 3

Follow these detailed tips to get the jobs you want. This installment focuses on the mold and the molding machine.

Read MoreTracing the History of Polymeric Materials: Celluloid & Film Stock

In this series we delve into a discerning look back into the history of our industry and how we all got here.

Read MoreGet Better at Quoting Injection Molded Parts: Part 2

Follow these detailed tips to get you the injection molding jobs you want. Here we factor in the costs of scrap and regrind, along with energy and certain additives.

Read More