Know-How

MATERIALS: Analysis Gone Wrong

A lot of resources are devoted each year to trying to figure out why products fail. Sometimes it’s because no one involved in a project realizes the data provided was wrong.

Read MoreInjection Molding Know How, Live

Upcoming training by Plastics Technology's Injection Molding Know How columnist, John Bozzelli, will walk injection molders through new tool process development via scientific molding.

Read MoreTOOLING: Designing the Tool for the Material

To design a mold for the widest processing window and the fewest problems, start by considering the conditions imposed by the material being run.

Read MoreEXTRUSION: About Your ‘General-Purpose’ Dies

There is no such thing. While dies can be adjusted to provide some flexibility, the fact is they are optimized for one specific output of one particular polymer.

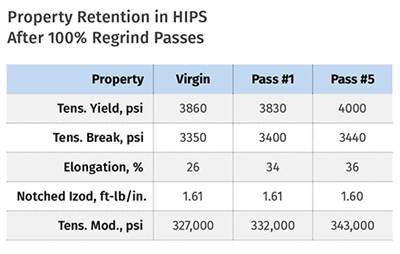

Read MoreINJECTION MOLDING: Another Way to Deal with Regrind

You can run into a lot of problems molding parts from a blend of regrind and virgin material. Might you be better off using 100% regrind?

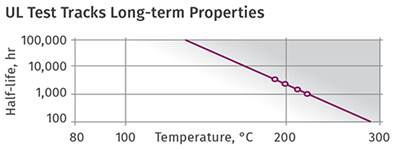

Read MoreThe Mystery Of Physical Aging, Part 3: Accelerated Aging Tests

Accelerated aging tests relied on by industries such as medical take into account only chemical aging—oxidation—and ignore physical aging.

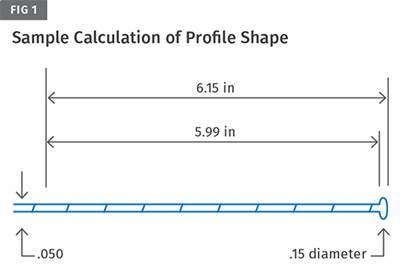

Read MoreThe Importance of Gate Geometry

Gate size and shape—unlike gate location—don’t often get the attention they deserve. Many common assumptions about gate geometry deserve to be challenged

Read MoreHow to Address Uneven Wall Thickness in Stretch-Blow Molding

Many conditions must be met to get the best wall distribution in a PET bottle. Skilled operators are, as always, indispensable.

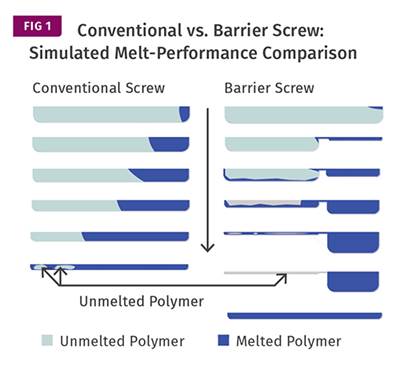

Read MoreUnderstanding Solids-Bed Breakup in Barrier Screws

Barrier screws all but eliminate problems associated with solids-bed breakup. But if they do occur, tremendous pressures can develop, causing screw wear.

Read MoreHigh-Pressure Water: A New Concept for Screw Cleaning

Everyone in a molding plant is on the same page for screw cleaning: Avoid pulling it until there is no alternative. Here are ways for dealing with the inevitable, including an altogether new technique.

Read More