Know-How

Extruding High-Temperature Resins

Older extrusion lines might not be suitable for processing materials up to 750 F. Here's what you need to know to get started.

Read MoreShutting Down & Starting Up An Injection Molding Machine

Whether your press is going down for repairs, a holiday, or a slow production schedule, proper shut-down and start-up procedures must be followed.

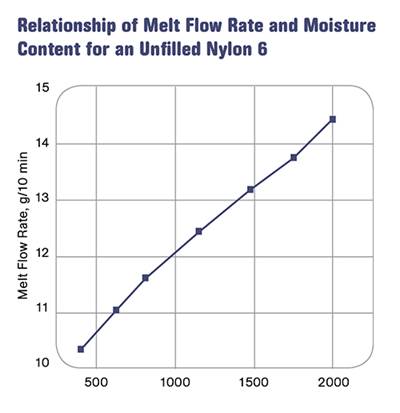

Read MoreMelt Flow Rate Testing–Part 8

Here are the steps to take in cases where the MFR is not provided by the polymer supplier.

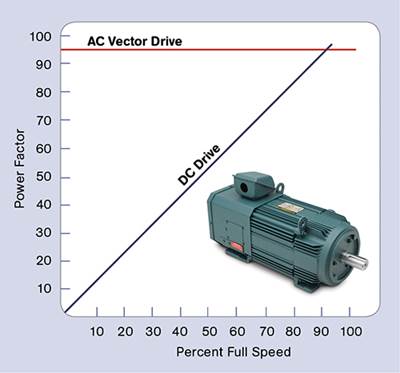

Read MoreAC Drives Take Hold

With progress in electronics and the introduction of the flux vector drive using complex control algorithms, AC drives are now equal to or better than DC drives for most applications.

Read MoreTelltale Temperatures

Here's how to get a 'feel' for a screw design without actually seeing it. And how to use this information.

Read MoreHow to Establish an Acceptable Range for Pressure at Transfer

Pressure at transfer tells you the viscosity of the resin, providing the fill time is the same. Monitoring pressure at transfer—or better yet, the integral under the pressure vs. time curve—provides insight into the process.

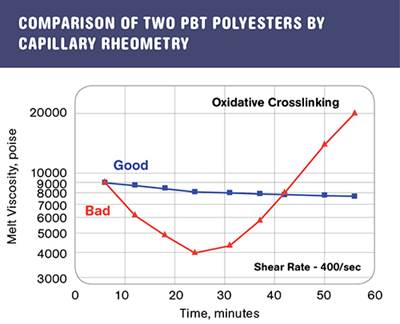

Read MoreMelt Flow Rate Testing—Part 6

Once degradation has been established, the discussion inevitably turns to how it happened. It might be expected that the answer to this question is widely known. Not so. The good news is that the influences that cause polymer degradation during processing are few.

Read MoreMinimizing Black Specks

Black specks in molded parts are one of the most infuriating problems to resolve on the shop floor. Here's how to fix them.

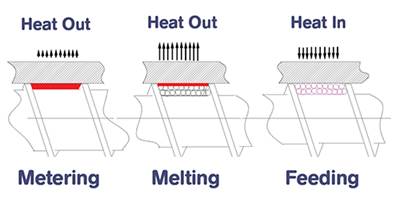

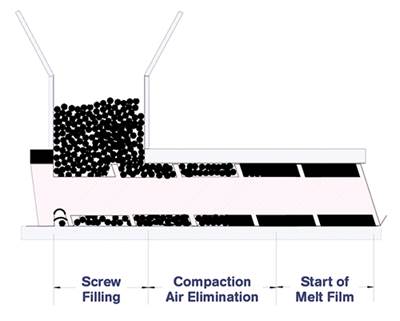

Read MoreDon’t Overlook the Feed Section

Most extrusion screw designers often do not design the feed section with the same rigor as other sections. This is odd since nothing goes through the screw that doesn鈥檛 first go through the feed section.

Read More