Know-How

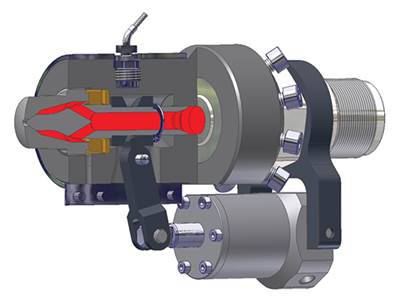

Minimize Screw Recovery & Cycle Times

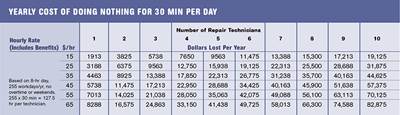

There are hundreds of details you must identify and control to run a successful molding plant. One that is almost always at the top of the list is optimizing cycle time. Shorter cycles that make acceptable parts improve profits.

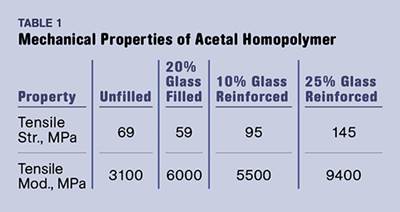

Read MoreDimensional Stability After Molding: Part 1

The degree to which molded parts shrink as they cool is largely dependent upon the composition of the material being processed.

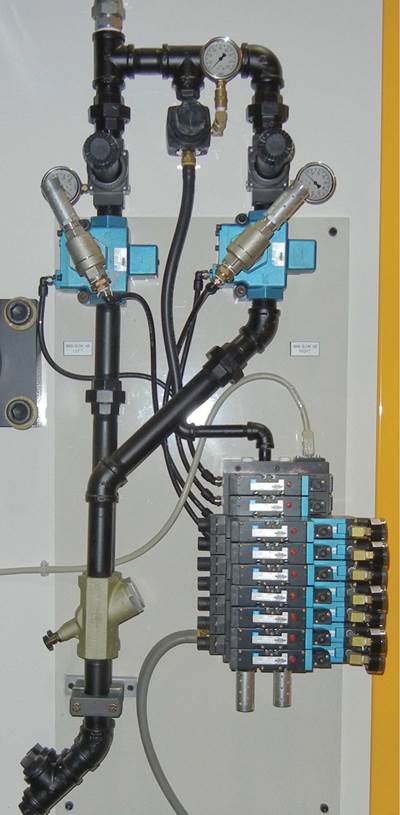

Read MoreThe Importance of Air Valves In Accumulator-Head Blow Molding

Proper air usage is an important part of making good blow molded parts.

Read MoreScrew Design Is a Matter of Balance

In order to achieve a balance between feeding, melting, and pumping it鈥檚 necessary to use proven calculations and/or tested empirical data in the design of each section.

Read MoreHow to Specify A Resin Dryer

To dry your polymer correctly you need a dryer that is properly designed and working properly. Here are my suggested specifications, for a two-, three- or four-bed desiccant dryer, the most common types used.

Read MoreWhat Output Should You Expect?

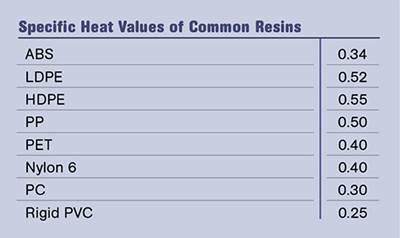

You can get a rough estimate of the potential output if you know the drive horsepower of your machine and the thermal characteristics of one of the materials you鈥檒l be running.

Read MoreTop 10 Reasons Why Molders Fail At Implementing ‘Scientific Molding

What is Scientific Molding? And why do molders seem to have such a difficult time embracing its concepts? Here are some thoughts on the matter.

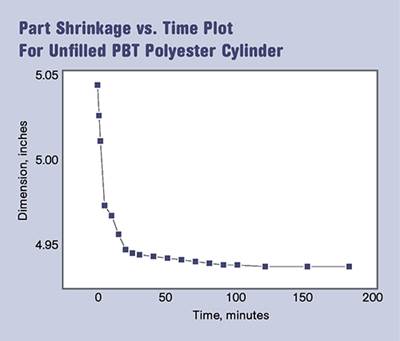

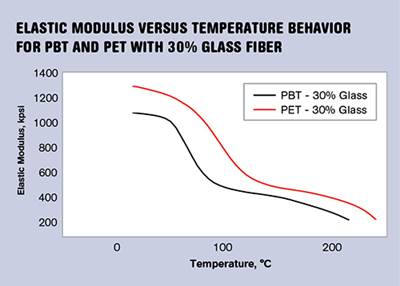

Read MorePBT & PET Polyester: Part 2 The Performance Factor

All things being equal, PET will outperform PBT mechanically and thermally. But the processor must dry the material properly and must understand the importance of mold temperature in achieving a degree of crystallinity that allows the natural advantages of the polymer to be realized.

Read More