Know-How

Screw Decompress Before Screw Rotate

Thoughtfully determining when to start screw rotation to build the charge for the next shot can reduce the wear and tear on the screw tip, check valve, and screw motor.

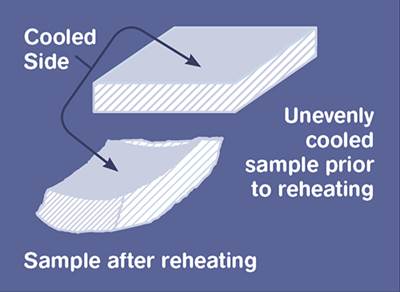

Read MoreDimensional Stability After Molding: Part 4

In the first three parts of this series we focused on those influences that cause molded parts to get smaller. But there are environmental factors that also cause parts to increase in size over time.

Read MoreCooling Tips for Crystalline Polymers

If a little cooling is good, is a lot of cooling better?

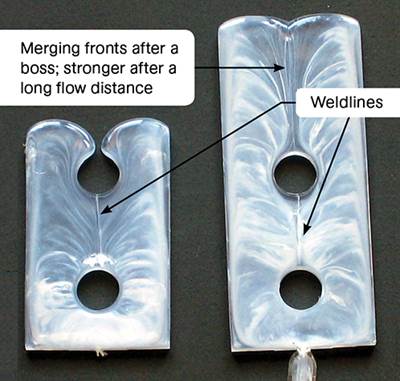

Read MoreCoping with Weak Weld Lines

Weld lines cause significant reject rates and are a common problem that all molders face.

Read MoreDimensional Stability after Molding—Part 3

Any process that involves melting and re-solidifying a polymer involves a compromise between achieving the perfect structure and producing a part that can be sold at a price that the market is willing to pay.

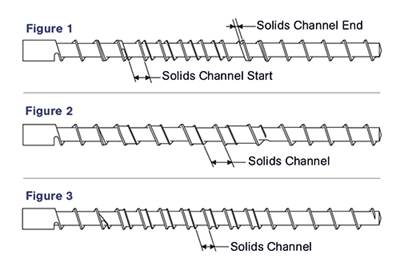

Read MoreThe Evolving Barrier Screw

There has been a gradual transition from the earlier Maillefer designs used in Europe to the Dray/Lawrence design using the parallel barrier design with an increased helix angle to accommodate wider channels.

Read MoreDimensional Stability After Molding—Part 2

After molding, acetal parts can continue to shrink at room temperature and even in the cold.

Read MoreMaintenance Training? Show Me the Money

Training works best if a goals are set and a plan is established to meet them.

Read MoreWhy I Still Like Analog Meters

They may not look as slick as their digital cousins, but I find them more helpful in identifying and troubleshooting extrusion problems.

Read More