Know-How

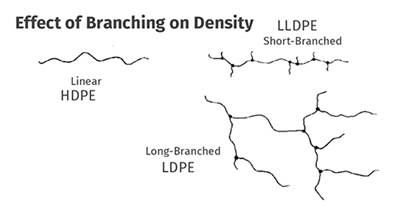

MATERIALS: Performance in Polyethylene: Density Matters

In polyethylene, density provides another mechanism to control properties. But it must be specified properly.

Read MoreINJECTION MOLDING: Troubleshooting Bridging

Bridging is an aggravating problem that can shut you down. Here's how to find it and fix it.

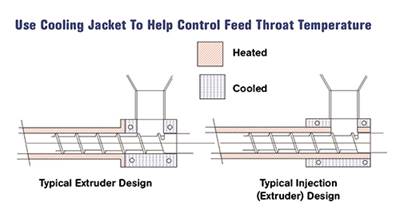

Read MoreEXTRUSION: What’s the Right Feed Throat Temperature?

Selecting the proper one is critical to the process.

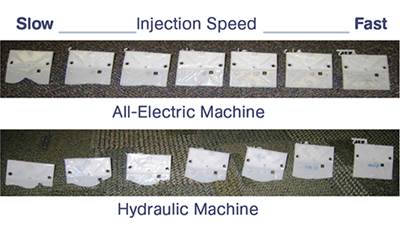

Read MoreINJECTION MOLDING: ‘Know Your Machine’

Many molders think they “know their machine,” but in reality do not. They get consumed by the demands of day-to-day production requirements and lose sight of the big picture.

Read MoreMATERIALS: Melt Flow Rate Testing—Part 10

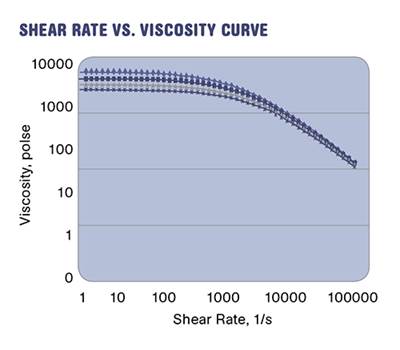

Two areas where the melt flow rate test it is not useful are related to processing.

Read MoreEXTRUSION: Effect of the Screw Flight On Melt Temperature, Energy Use

So-called rules of thumb regarding the design of flight clearance and width do not consider the temperature effect, both from the point of view of melt temperature and energy efficiency.

Read MoreA Better Way to Balance Die Flow

Use temperature adjustments before making any mechanical tweaks.

Read MoreScrew Speed Versus Recovery Time

Many molders don't take screw-rotation speed into account when developing a process for a new mold. Here's why they should.

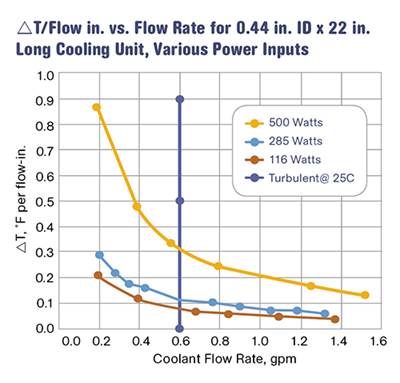

Read MoreLeverage Your Cooling Power

You can predict the amount of heat you'll need to remove from parts before ejection with reasonable accuracy if you know polymer thermal properties and certain other rules of thumb.

Read More