processing tips

Cycle Time: Science vs. Rules of Thumb—Part 4

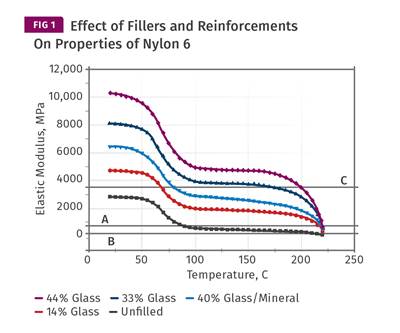

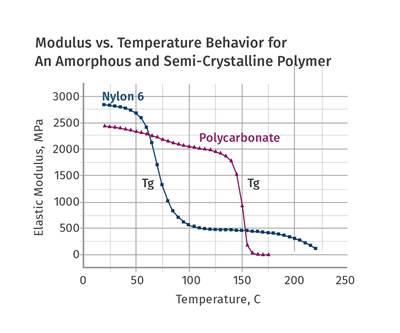

While laboratory tests are helpful in determining how polymers behave, you must remember the fundamental differences between laboratory measurements and the real world of plastic processing. Let’s examine semi-crystalline polymers here.

Read MoreHow Low Can Low-Rate Feeders Go?

More and more processors are looking for greater precision from their feeding equipment. Here’s what some are doing about it.

Read MoreKeep Dust and Angel Hair Out of Your Process

Angel hair, fines, and dust can adversely impact any type of plastics production—from resin manufacturing itself to molding and other processes. Here’s how to solve it.

Read MorePolyolefin Discoloration: New Additive Solutions Solve Common Problems

There’s a growing demand for PE films with lower initial color and improved color stability, as well as better retention of physical properties. New stabilizer systems address these and similar concerns for molded PE and PP parts.

Read MoreMaterials: Cycle Time: Science vs. Rules of Thumb—Part 2

Understanding cooling—how a given material develops modulus as it solidifies—requires access to data that provides some insight into the relationship between modulus and temperature. Dynamic mechanical analysis is a helpful tool.

Read MoreUnderstanding Low-Rate Feeding for Continuous and Batch Processes

Molders and extruders that need to feed tiny amounts of material to their process require precision in both the material being fed and the equipment doing the dosing. When a shot size consists of three pellets, there is no margin for error.

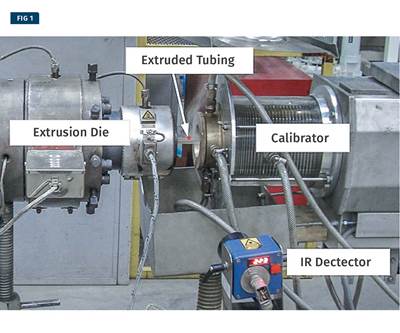

Read MoreHow to Collect and Interpret Extrusion Process Data; Part 3

In this final installment, learn how process data can be used to identify and fix extrusion issues.

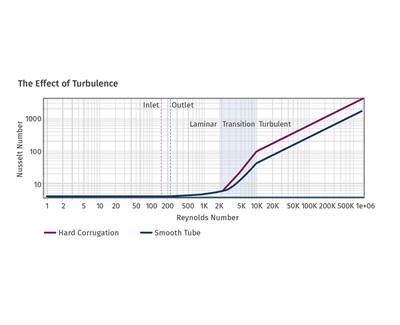

Read MoreExtrusion Cooling: It’s All About Turbulence

Regardless of what you are extruding, in order to maximize cooling you need to generate turbulence at the heat-exchange surface.

Read MoreInjection Molding: Are You Using More Than 65% Of Your Barrel Capacity?

If you are, you are inviting Murphy—as in trouble—to the party.

Read MoreHow to Solve Common Ultrasonic Welding Problems

Understand and address the likely origins of welding problems to keep production on track.

Read More