processing tips

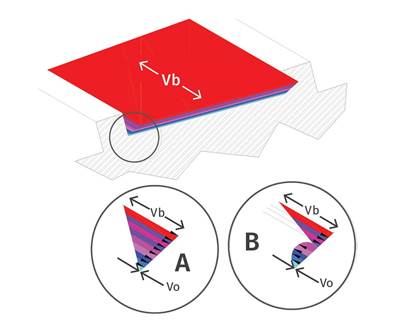

A Processor’s Most Important Job, Part 8: Molded-In Stress

How processing adjustments can control molded-in stress.

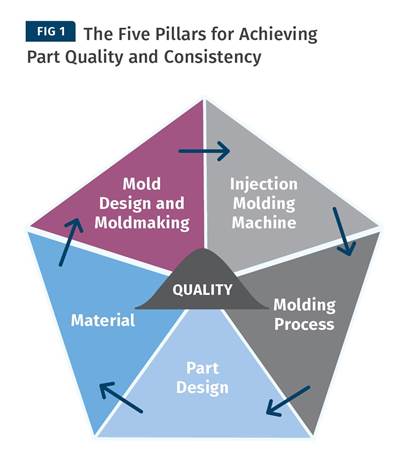

Read MoreImproving Molding Process Capability: The Role of the Five Essential Pillars, Part 2

Each contributes to molded-part quality, and each must be optimized before production begins.

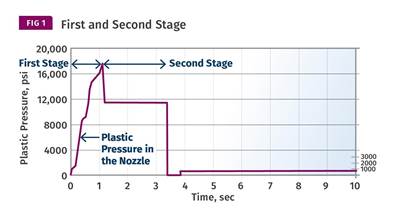

Read MoreInjection Molding: Fill Based on Volume, Not Weight

Most parts should be 90-99% full after first-stage—by volume not weight. Here’s why that’s important and how to make a first-stage-only part.

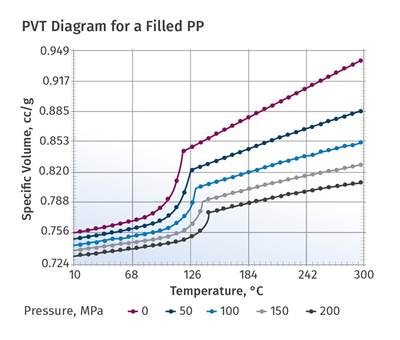

Read MoreA Processor's Most Important Job, Part 7: Reviewing Crystallinity

There are several process-related issues that influence crystallinity besides cooling rate. Let’s examine a few.

Read MoreExtrusion: A Simple Way to Evaluate Your Screw Performance, Part 2

A hand-held calculator and some basic equations can help determine whether your screw is up to snuff.

Read MoreInjection Molding: Safety First—Know the Compatibility of Different Resins

Certain materials don’t play well together when mixed. So it’s best not to. Here are some guidelines.

Read MoreRapid Heat & Cool Molding Evolves to Meet Industry Challenges

Technical capabilities of the process have advanced to erase former cycle-time penalties, and ongoing developments address creation of a materials database and new applications in hybrid composite injection overmolding.

Read MoreInjection Molding: Process Documentation Is Crucial to Making ‘Identical’ Parts

Use a machine/mold setup sheet to document plastic parameters and use them on any acceptable machine into which the mold is placed.

Read MoreTooling: Clamp Pressure and Cavity Land Area

What you need to know to prevent flashing and mold damage.

Read MoreInjection Molding: A Practical Approach to Calculating Residence Time

Toss the formulas. The best way to determine residence time is to conduct a simple experiment.

Read More