processing tips

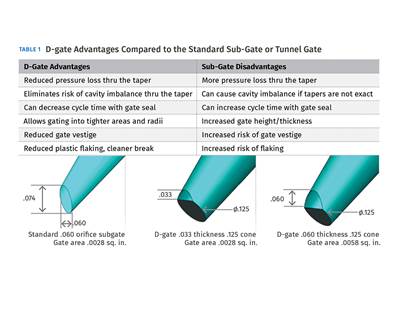

Gating Revisited

An overlooked factor in injection molding has outsize influence on the process and part quality.

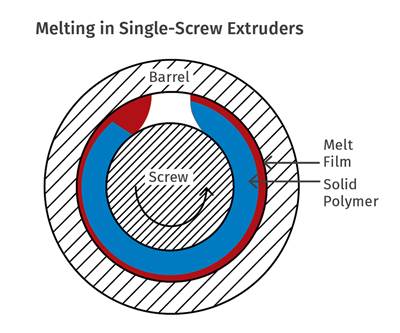

Read MoreWhat Output Can I Expect?

Processors ask screw designers this question a lot. But neither output nor melt temperature can be predicted without details on the polymer and head pressure.

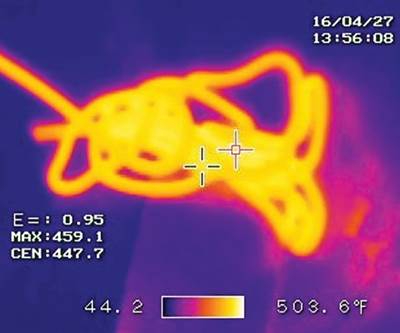

Read MoreUnraveling the Mysteries of Melt Temperature

Infrared technology can provide consistent and accurate readings of melt temperature. Here’s how to use it.

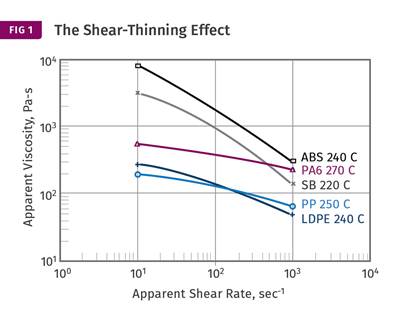

Read MoreExtruding Very High-Flow Polymers

Screw designs not suited to process lower-viscosity materials will result in poor melt quality and lower outputs.

Read MoreFaster Is Not Always Better—Optimize Your Molding Cycle

It is possible for machines to run too fast, so find the sweet spot where maximum output overlaps with good parts.

Read MoreSolving Issues with Gloss

Your problem may be related to tooling, material, processing, or combinations thereof. Here’s how to find the root cause.

Read MoreAvoid These Three Mistakes to Get the Most from Color

Here are the key misconceptions and common practices that keep processors from reaching the heights of coloring proficiency. Find out if you’re stumbling into these pitfalls, and learn how and why you should swerve around them

Read MoreFive Effective Ways to Control Color

A 50-year veteran in color-concentrate production and use shares practices to help you make better color decisions and generate less scrap. To specify color correctly and communicate your specs to your color supplier requires understanding of the “Five U’s.”

Read MoreWhat You Should Know About Molding Wood-Plastic Composites

Originally targeted mainly for extrusion, new options for wood-plastic composites have been optimized to open doors for injection molding applications.

Read More