processing tips

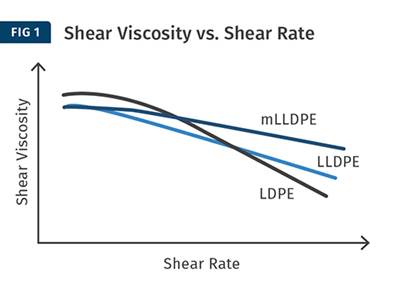

Coextruding Blown Film Needs Deeper Understanding of Resin Rheology & Die Design

More film processors are investing in lines with nine or more layers. With more resin possibilities and combinations coming into play, it’s important to learn more about material rheology and compatibility, as well as die design.

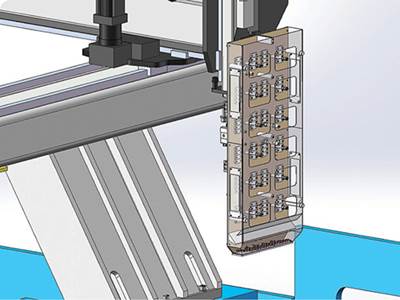

Read MoreRobot End-of-Arm Tooling: Making a Big Difference

Often overlooked as a small part of an automation system, clever end-of-arm tooling techniques and designs can improve part quality, heighten efficiency, and eliminate headaches for any molder.

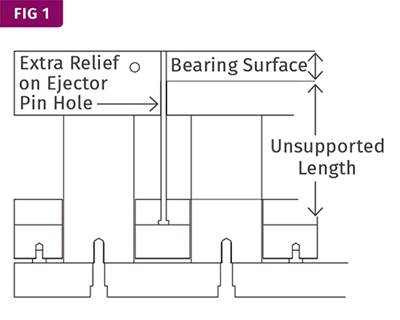

Read MoreTOOLING: Ejectors: Watch That ‘Unsupported Length’

It may be an unfamiliar term, but it’s the key to preventing ejector-pin deflection and breakage

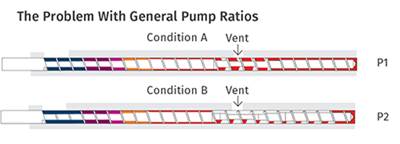

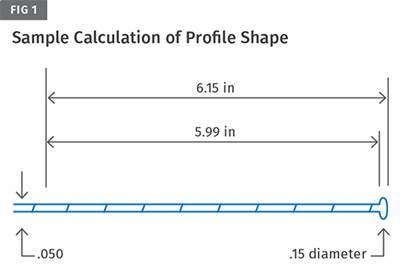

Read MoreEXTRUSION: Avoid General ‘Pump Ratios’ On Two-Stage Screws

Instead, rely on basic data and calculations to determine the proper depth of the first and second metering sections

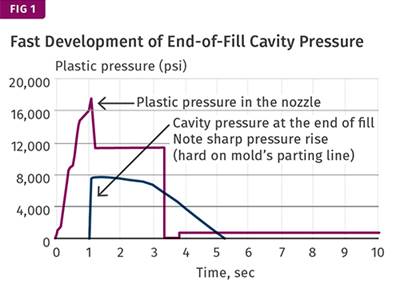

Read MoreINJECTION: First to Second Stage Transfer: Should There Be ‘Bounce-Back’?

How much screw ‘jumping’ or bounce-back can your process tolerate? The answer is no surprise: It depends

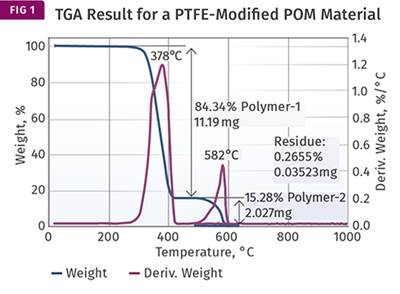

Read MoreMATERIALS: Analysis Gone Wrong

A lot of resources are devoted each year to trying to figure out why products fail. Sometimes it’s because no one involved in a project realizes the data provided was wrong.

Read MoreTry Multilayer Injection for Efficient Molding of Thick-Walled Lenses

A new approach to multilayer injection molding boosts productivity in making challenging optical plastic parts, such as thick-walled LED lenses for automotive headlights, which have tolerances in the micron range.

Read MorePut the Brakes on Resin Conveying Speed to Minimize System Maintenance

Here’s how to manage pneumatic conveying speeds to extend equipment life and reduce material waste in your plant.

Read MoreTOOLING: Designing the Tool for the Material

To design a mold for the widest processing window and the fewest problems, start by considering the conditions imposed by the material being run.

Read MoreEXTRUSION: About Your ‘General-Purpose’ Dies

There is no such thing. While dies can be adjusted to provide some flexibility, the fact is they are optimized for one specific output of one particular polymer.

Read More