processing tips

Your Options for Mold Venting

When should you use machined vents or porous, sintered metals? Here are some guidelines.

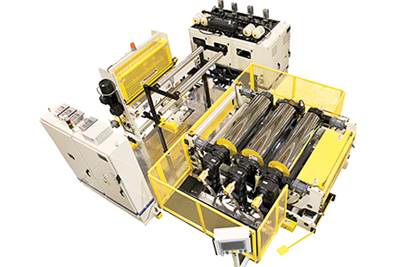

Read MoreOptimizing Thin-Gauge Sheet for In-Line Thermoforming

Processing thin-gauge sheet for in-line thermoforming poses unique challenges. Here’s how to cope with them.

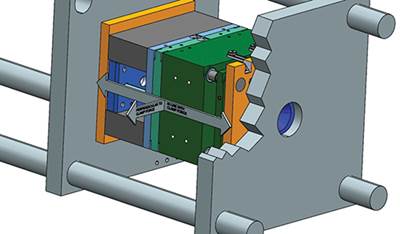

Read MoreTOOLING: Flash-Free Molding: Part Two

Parting-line maintenance, mold spotting, and machine conditions can all contribute to flash.

Read MoreINJECTION MOLDING: How to Tell If Your Non-Return Valve Is Leaking

Check valves are potentially troublesome devices. Here’s how to find out if yours is behaving properly.

Read MoreThe Mystery of Physical Aging, Part 1: Knowing the Difference

In polymers, aging is commonly considered essentially synonymous with oxidation. But there are important differences between this type of chemical aging and less commonly recognized physical aging. Let’s unlock the mystery.

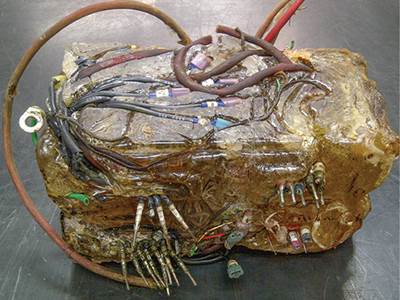

Read MorePrevent & Minimize Downtime in Hot Runner Molding

There are simple explanations for the most common hot-runner problems and equally simple ways to prevent them. One is to take advantage of features often overlooked in today’s hot-runner controls.

Read MoreThe Paradox of Proportioning

Continuous proportioning typically involves a group of gravimetric feeders operating under some form of higher level coordinating control. One would think the result should be a perfectly formulated composite stream. But the devil is in the details.

Read MoreAutomation Eliminates Contamination

Many molders use robots to boost output and repeatability, but SSI also uses them to prevent contamination of critical diagnostic products.

Read MoreTOOLING: Flash-Free Molding: Part 1

A robust process window relies a lot on tooling. So it stands to reason that making a tool change to address issues provides a more robust solution

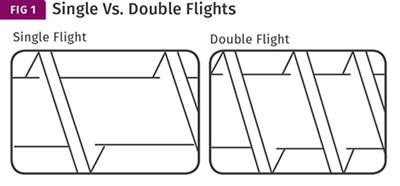

Read MoreEXTRUSION: Double Flights Are Not a Cure-All

There are certain applications where double-flighted feed sections make sense, and others where they don’t.

Read More