processing tips

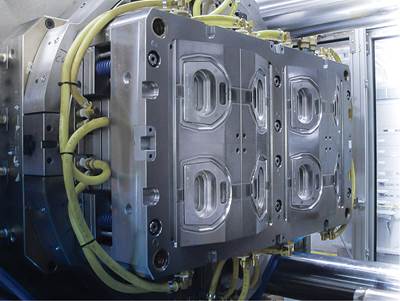

TOOLING: Balancing the Heat Budget In Injection Molds

Basic formulas for how much heat you must pull out of the mold to achieve a set cycle time

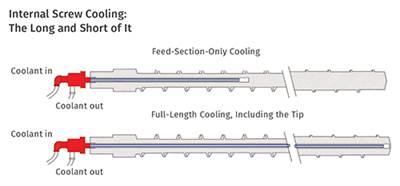

Read MoreEXTRUSION: When Internal Screw Cooling Makes Sense

Internal screw cooling could help you solve solids-feeding and burning problems.

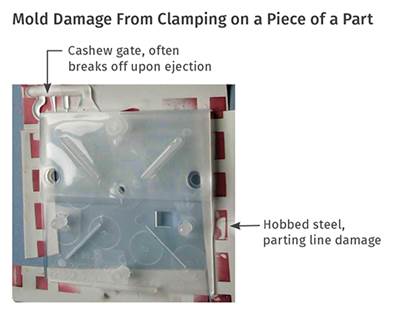

Read MoreINJECTION MOLDING: Setting Mold Protection Takes Time But Saves More

Mold protection is often neglected, but it more than pays for the time and attention required.

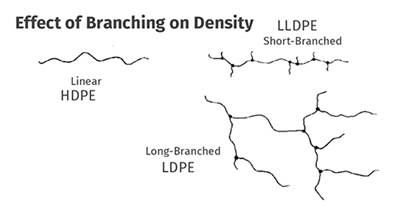

Read MoreMATERIALS: Performance in Polyethylene: Density Matters

In polyethylene, density provides another mechanism to control properties. But it must be specified properly.

Read MoreSolutions to Batch Blender Issues Save Money & Downtime

When a blender is operating poorly, odds are that the fixes are quite simple if you know what to look for.

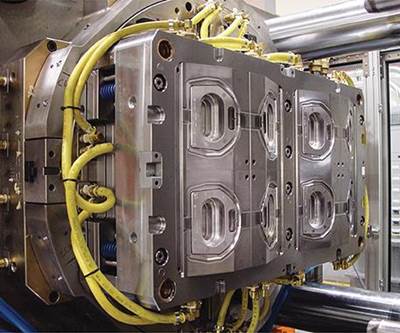

Read MoreMulti-Component Molding: Which Way Should You Go?

Moldmaker and injection molder MGS Mfg. Group details different technical options and how they mesh with various market opportunities.

Read MoreINJECTION MOLDING: Troubleshooting Bridging

Bridging is an aggravating problem that can shut you down. Here's how to find it and fix it.

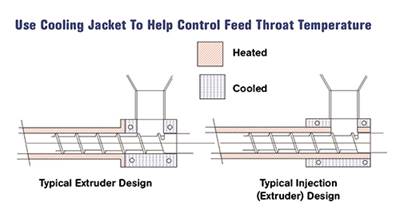

Read MoreEXTRUSION: What’s the Right Feed Throat Temperature?

Selecting the proper one is critical to the process.

Read MoreBozzelli’s Dozen Drying Tips

There’s a lot to know about drying—enough to fill a book, at least. But for now, here are a dozen details you need to know, from seasoned injection molding consultant and Scientific Molding trainer John Bozzelli. Scroll down and take his quiz.

Read MoreModular Conveyors Help Molder Automate Quality Control

Easily reconfigurable belt conveyors provided one molder a convenient means of 100% QC inspection for tramp metal.

Read More