Tooling

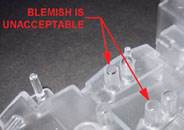

Flow Analysis Gets It Right the First Time

This molder's trial parts showed visible flaws that made them unusable. Simple changes in tooling, processing, or materials couldn't fix it. But flow simulation provided an answer that worked right off the bat.

Read MoreUnscrewing Molds Go Electric

Hydraulics are the usual power source driving unscrewing cores to separate threaded parts from injection tools.

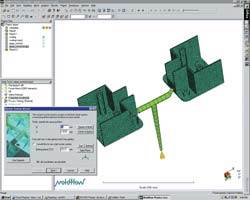

Read MoreMolding Simulation Gets Easier Than Ever

In the mid-'90s, when Peter Rucinski worked for a plastics resin supplier, he broke his company's record by performing 30 mold simulations in one year.

Read MoreSecrets of Successful Thin-Wall Molding

Demands to create smaller, lighter parts have made thin-wall molding one of the most sought after capabilities for an injection molder.

Read MoreDetermining Maximum Mold Cycle Counts

The first production meeting with my new employer went something like this: “We want you to establish a preventive maintenance program that is based on cycle counts for all our molds.” Before I could launch into an explanation of how best to determine maximum cycle counts, I was hit with this: “So, how many cycles do you think our molds can safely run before we need to clean them?”Leaving my crystal ball at home and unable to get my x-ray vision working, there was no way to answer that question with any accuracy.

Read MorePlastics Training Enters Virtual Reality

Plastics processors are discovering two employee training programs initiated this year that offer instruction in a “virtual” space, where the student can interact with the instructor and course materials via a satellite dish or the internet.

Read MoreRoyal Plastic to Make Laser-Sintered PEEK Aircraft Parts

Aerospace composite fabricator Royal Plastic Mfg., Minden, Neb., is expanding into the emerging field of rapid manufacturing with the purchase of the first Eosint P 800 laser sintering machine in North America from EOS of North America Inc., Novi, Mich.

Read MoreHot/Cold Thermal Cycling of Injection Molds Heats Up

Injection molders are warming up to the idea of cycling their tool surface temperature during the molding cycle rather than keeping it constant.

Read MoreWhen Assembling Molds, Patience is THE Virtue

Installing and fitting close-tolerance tooling requires patience, a steady hand, attention to detail, and the ability to “read” resistance.

Read More