Tooling

What Toolroom Maintenance Supervisors Need to Know-Part II

September’s “Mold Shop” column presented an overview of a mold maintenance supervisor’s need-to-know priorities.

Read MoreVacuum Venting Keeps Molds Running Longer

In tough economic times, facing hungry competition here and abroad, molders cannot afford to ignore preventable problems that slow cycles, cost machine downtime and mold maintenance, and waste material on reject parts.

Read MoreUnbalanced? No Shortage of Ways to Fix Uneven Filling of Multi-Cavity Molds

The accepted ground rule for balancing melt flow in multi-cavity injection molds is to achieve equal flow distance from the injection point to each cavity.

Read MoreNovel Ejector System Eliminates Plates and Pins

Injection mold cost savings, greater molding productivity, and better part quality are promised for a new ejection system that does away with conventional ejector plates, housings, pins, and risers. This approach is said to reduce mold height, shorten mold-open times by at least 10%, enable better optimization of mold cooling鈥攏ot to mention eliminating ejector marks on parts.

Read MoreCleaning Molds in the Press Slashes Downtime

For a global electronics manufacturer with around-the-clock production, the ability to clean molds in the press without disassembly provided major productivity increases.

Read MoreWhat Toolroom Maintenance Supervisors Need to Know

Those in charge of keeping molds reliable and production-ready normally start their day in the same manner—wondering what broke down since they last walked out the door—and hoping they have the resources to get it going again.

Read MoreRapid Tooling “Grows” Profits At Linear Mold

Rapid manufacturing technologies tend to be focused primarily on making prototype and sometimes production parts.

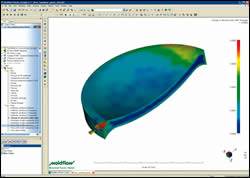

Read MoreMolding Simulation: New Frontiers in Process Prediction

Software suppliers agree that 3D simulation of injection mold filling, packing, cooling, shrinkage, and warpage is fairly mature.

Read MoreWhy Mold-Maintenance Data Is Essential for Processing Technicians

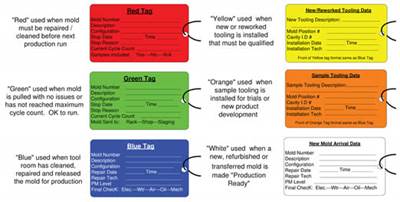

When I was in the Navy, many different trades such as hydraulics, electrical, airframes, armament, and jet-engine mechanics worked side by side to get planes into the air, through their scheduled missions, returned to base, and turned around to do it all over again.

Read MoreHot-Runner Controller For Up to 256 zones

WEB EXCLUSIVE A new hot-runner temperature controller for six to 256 zones was unveiled at the recent Chinaplas show in Shanghai by Yudo Co.

Read More