Tooling

Defect Position Analysis: What It Is, Why You Need It

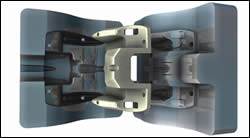

There are so many new technological options in mold design, moldmaking, and molding today that it boggles the mind: We can simulate melt flows to anticipate difficulties.

Read MoreQualifying an Outside Molder? Look at the Tool Room

If custom molders were judged on curb appeal alone, this one would always be flush with work. Appointed in colonial brick encasing large smoked-glass windows and surrounded by balmy landscape and a lawn that looked good enough to eat, this stately plastics plant just screamed money. Surely they must be doing something right. But once past the glitz, the show was over.

Read MoreThe Final Check

The roar of fighter jets taking off one after another drowned out the frantic screams of the plane captain running towards me, but the look on his face made it obvious there was a problem.

Read MoreCAD Evolution For 3D Mold Design

Specially tailored packages of 3D computer-aided design software have been available to injection mold designers for at least a decade.

Read MoreCoatings Give Aluminum Molds Cost/Performance Edge Over Steel

New cost-effective technologies are designed to make aluminum an attractive alternative to tool steels in a range of plastics molding processes. One method uses a plasma technique to convert the aluminum surface into a hard, dense, wear-resistant ceramic. Another approach uses electro-deposition to apply a surface coating with high hardness, corrosion resistance, and chemical resistance.

Read MoreConair and Husky Jointly Offer PET Systems

WEB EXCLUSIVE The Conair Group, Inc., Cranberry Township, Pa., and Husky Injection Molding Systems Ltd., Bolton, Ont., have agreed to jointly supply complete PET preform manufacturing systems worldwide.

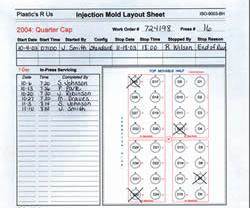

Read MoreCreating a Mold-Repair Plan-Part II: The Last Shot Inspection Report

Last month, we discussed how to collect accurate mold performance data at the press through the use of an IML (injection mold layout) sheet.

Read MoreCreating a Mold-Repair Plan-Part I: The Mold Layout Sheet

Regardless of mold type, the goal of the maintenance shop always is the same: Get a mold production-ready after it has been removed from service.

Read MoreOne Method Can Diagnose Six Main Causes of Bad Parts

World-class lean-manufacturing principles and total quality programs will not necessarily prevent an injection molder from making occasional bad or suspect parts.

Read More