Know-How

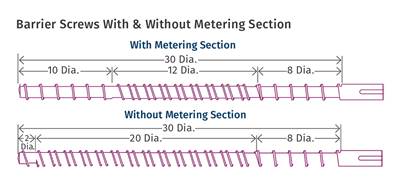

Extrusion: Barrier Screws: Metering Section or Not?

A barrier screw without a metering section can reduce output and increase melt temperature.

Read MoreInjection Molding: A Practical Approach to Calculating Residence Time

Toss the formulas. The best way to determine residence time is to conduct a simple experiment.

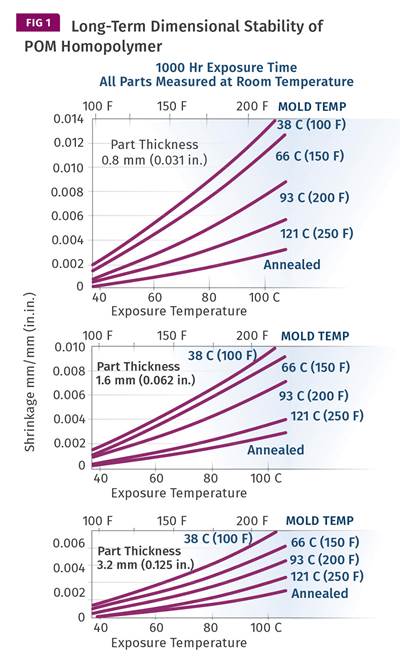

Read MoreA Processor's Most Important Job, Part 5: POM Polymers

Using a mold temperature above a polymer’s Tg ensures a degree of crystallinity high enough to provide for dimensional stability, even if the part must be used at elevated temperatures. But POM is an exception. Why?

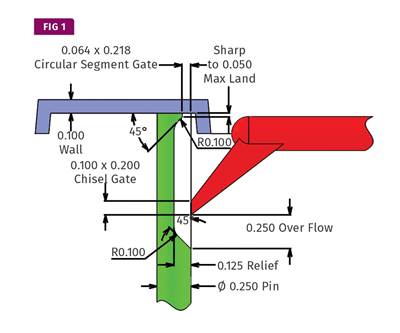

Read MoreTooling: What You Need to Know About Jump Gates

Many molders don’t care for jump gates because they have to process around them. But here are some tricks of the trade.

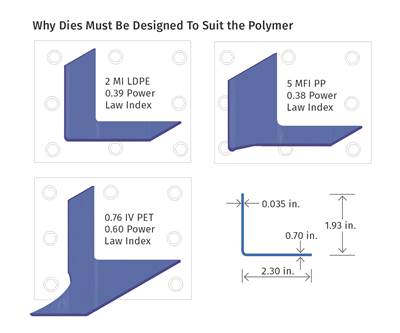

Read MoreExtrusion: Why There Are No Truly Universal Dies

Flow characteristics of different polymers vary considerably. So while adjustment features are available, for the most part dies must be designed for an individual polymer.

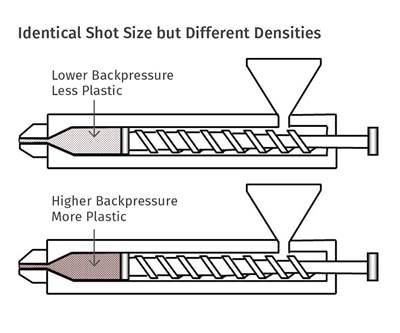

Read MoreInjection Molding: How Backpressure Adjustments Influence Shot Size

Raising backpressure results in increasing shot size, which can cause a host of other problems.

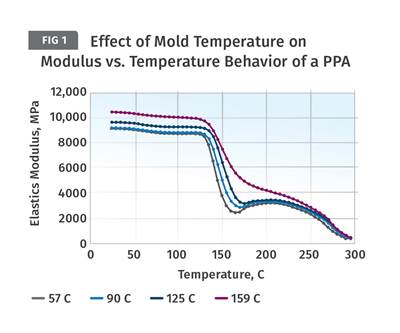

Read MoreA Processor’s Most Important Job, Part 4: Mold Temperature

Engineering polymers require higher mold temperatures to achieve their ideal structure. The temptation to turn down the mold temperatures can hurt part performance.

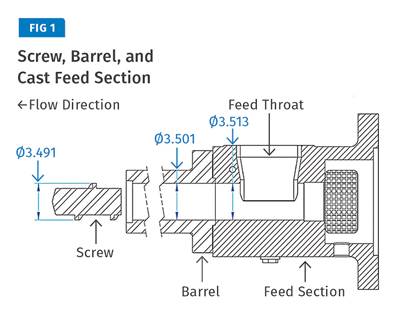

Read MoreCast vs. Integral: Which Feed Section Is Best for You?

Here are seven factors extrusion processors should weigh to help them decide between cast feed section versus an integral extrusion feed section.

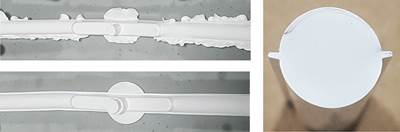

Read MoreTooling: Hot Sprues—Mold a Disk or Not?

Having a hot sprue shut off against the parting line versus intentionally molding a thin disk has been the subject of controversy for many years.

Read MoreExtrusion: Understanding Weld Failures

Hard-surfacing failures without evidence of burrs indicate possible weld bond issues.

Read More