Know-How

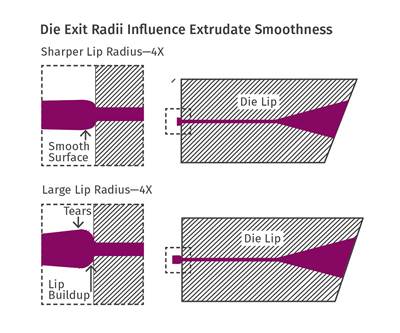

Sharper Dies Make for Smoother Extrusions

Dies that have a radius at the exit will result in poorer surface finish.

Read MoreClamp Tonnage: More Is Better...Right?

Determining the correct tonnage provides a foundation that must be rock-solid to avoid flash and damage. But applying excessive force can create problems with the part, mold, and machine.

Read MoreCycle Time: Science vs. Rules of Thumb, Part 1

What temperature must the polymer reach so the part can be ejected from the mold? Here, more than for any other variable, ‘rules of thumb’ unfortunately prevail.

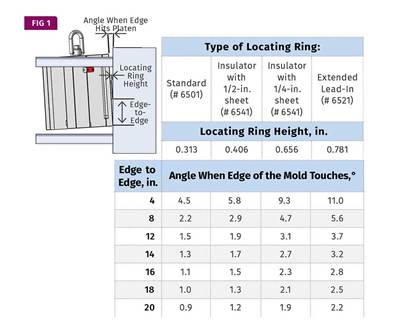

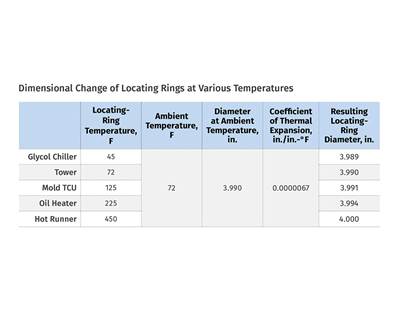

Read MoreLocating Rings, Platen Damage, and the Center of Gravity: Part 3

Selecting the right locating ring and putting it to good use takes careful consideration.

Read MoreSizing the Barrier Gap

Here’s a less complex way to properly size the barrier gap for barrier screws.

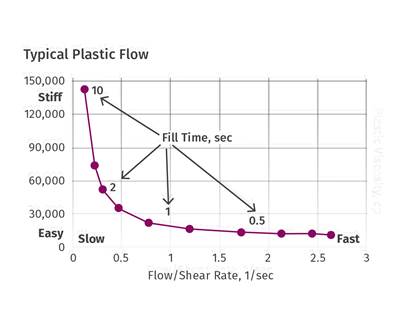

Read MoreHow to Duplicate a Process From Press to Press

To adopt the right approach you must distinguish between machine and plastic parameters.

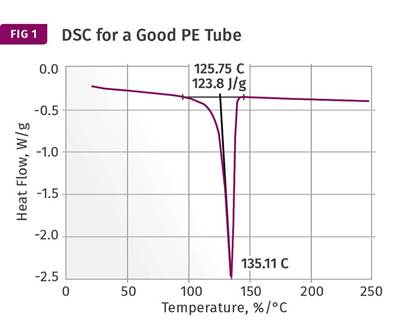

Read MoreThe Need for Generalists: Part 4

Solving problems generally requires distinguishing good samples from bad ones. But that can become clumsy when one person runs the test while another analyzes the data.

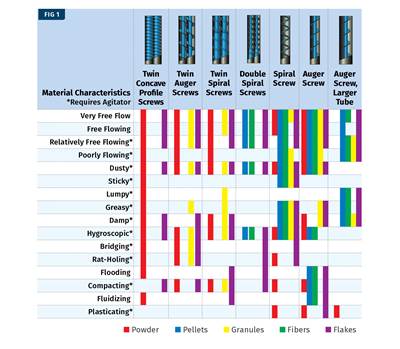

Read MoreOptimize Feeding to Get More Money in Twin-Screw Compounding

Follow these practical examples to improve the feeding efficiency and productivity of your process.

Read MoreLocating Rings and Platen Damage: Part 2

Selecting the right locating ring and putting it to good use takes careful consideration.

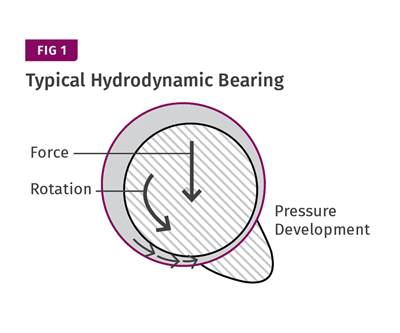

Read MoreHow ‘Hydro Wedges’ Reduce Screw Wear

Using them only in the melting section provides for greater design freedom and negates the impact these devices can have on output and melt temperature.

Read More