Know-How

How to Collect & Interpret Process Data in Extrusion: Part 1

The first installment of this three-part series focuses on proper use of a data- acquisition system.

Read MoreHitting the Numbers, Part 1: Communication is Key

Start with an up-front review, discussion and collaboration with the customer.

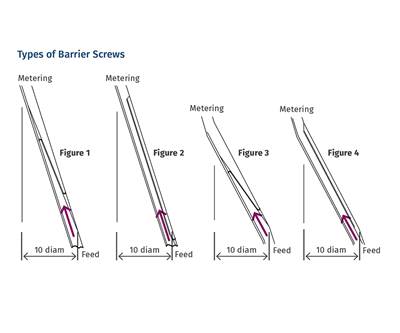

Read MoreWhich Barrier Screw for You?

It depends ... mostly on the melting requirements of the polymer.

Read MoreThe Need for Generalists: Part 1

Even companies with seemingly unlimited resources can have problems identifying root causes of problems. Maybe they have too many specialists and not enough generalists.

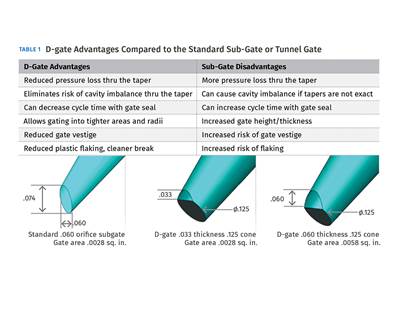

Read MoreGating Revisited

An overlooked factor in injection molding has outsize influence on the process and part quality.

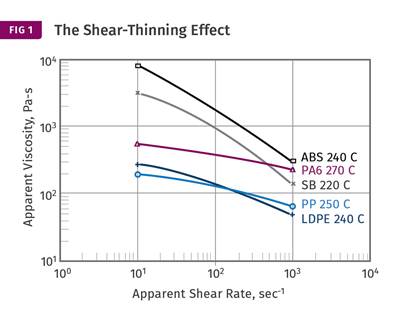

Read MoreWhat Output Can I Expect?

Processors ask screw designers this question a lot. But neither output nor melt temperature can be predicted without details on the polymer and head pressure.

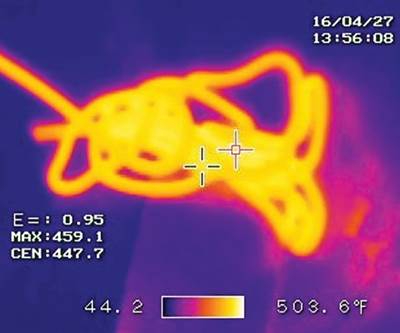

Read MoreUnraveling the Mysteries of Melt Temperature

Infrared technology can provide consistent and accurate readings of melt temperature. Here’s how to use it.

Read MoreFinding Root Causes of a Material Problem

Tools and methods for determining oxidative stability can be useful, but even more useful if constructed to yield the information you really need.

Read MoreWhat Blow Molders Say About All-Electric Machines

They are well established in Europe, but molders in North America are just beginning to come around to all-electrics’ improved performance, maintenance, cleanliness, and—yes— energy efficiency. Here’s first-hand testimony, from the U.S. and abroad.

Read MoreTwo-Shot Molding and Tool Design

There are a few variations of the two-shot molding process, and each has implications for tool design.

Read More