Know-How

INJECTION MOLDING: Improving Barrel-Temperature Measurement and Control

Proper thermocouple placement and contact area are crucial, as is wire maintenance. But remember that barrel temperature and melt temperature are not the same

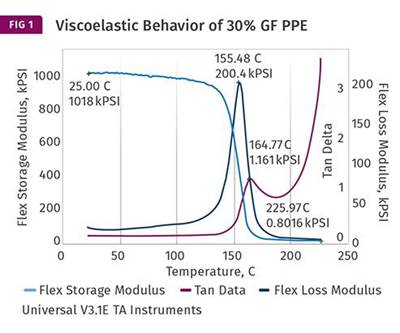

Read MoreMATERIALS: The Problems with Single-Point Data: Part 9

Time—and not just temperature—governs the behavior of materials under load. Both must be considered when evaluating a polymer for an application.

Read MoreRECYCLING: The Importance of Quality-Assurance Testing for Recycled Materials

Consider investing in these tools to ensure your material makes the grade.

Read MoreTOOLING: Designing Molds for Easy Cleaning & Maintenance in the Press

Pay attention to water leaks and rust, proper grease selection, vent buildup, and checks for wear.

Read MoreEXTRUSION: Managing Regrind

Reusing scrap is a necessary evil. But be aware of the negative impact scrap has on properties and extrusion efficiencies. Start by developing a regrind-usage program.

Read MoreINJECTION MOLDING: Get Control Over Barrel Zone Temperature Override

Poor temperature control results in an erratic melt stream and process. Here are some tips on how to get things under control.

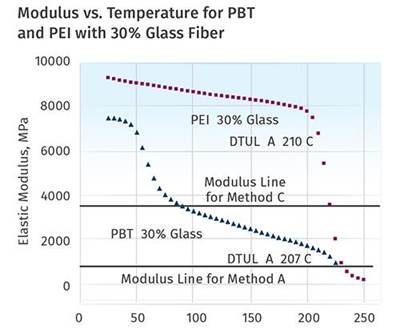

Read MoreMATERIALS: The Problems with Single-Point Data, Part 8

DTUL tests may have made sense in the 1940s and 1950s, before the advent of dynamic mechanical analysis. But designers and engineers today need better tools.

Read MoreTOOLING: Designing Molds for Easy Maintenance in the Press, Part 1

Attention to design of cooling, ejection, and slides can save downtime and maintenance headaches.

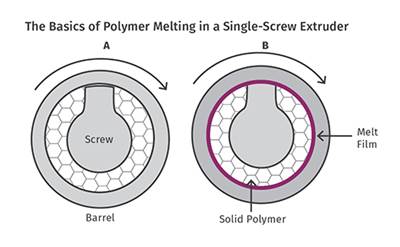

Read MoreEXTRUSION: Melting 101

Learn the basics on how polymer melts in a single screw. Barrel temperature plays less of a role than you might think.

Read MoreINJECTION MOLDING: Develop Guidelines—Not Strict Procedures— For a Robust Molding Process

‘Fool-proof’ dos and don’ts will prove foolhardy in a process with so many variables. You aren’t slinging burgers.

Read More