Know-How

MATERIALS: The Problems with Single-Point Data

It’s time for material suppliers to take a fresh approach to providing data. Thankfully, things are starting to move in that direction. Part 12 of 12.

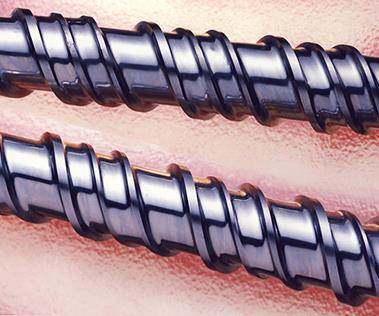

Read MoreEXTRUSION: Finding the Sweet Spot in Screw Design

The compression ratio of a screw does not provide enough detail on how it will perform. Screw design is a balancing act that takes many variables into account.

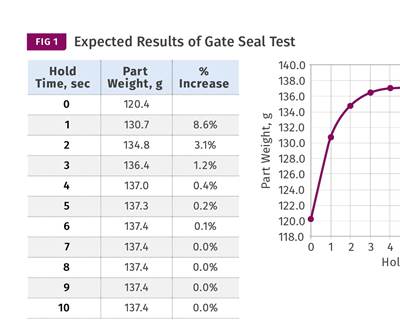

Read MoreINJECTION MOLDING: Gate Freeze Study: Danger in a Name?

The test actually determines the hold time needed to mold repeatable parts, and it should be done regardless of whether the gate freezes or not.

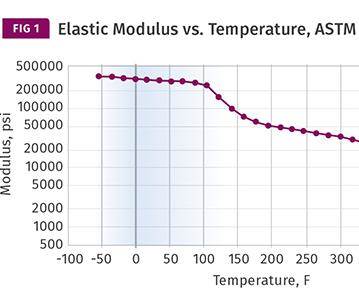

Read MoreMATERIALS:The Problems with Single-Point Data

This real-world scenario explains why molders and their customers need to ‘think in terms of graphs’ and gather as much data as possible before selecting a material for an application. Part 11.

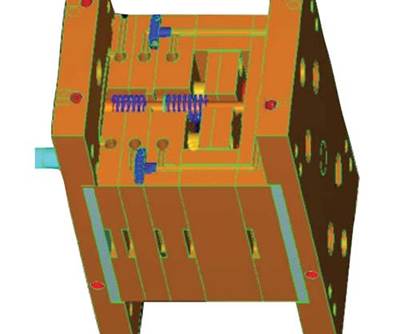

Read MoreINJECTION MOLDING: Properly Placing & Cooling Insulator Plates

Thermal-energy management from the mold to the platens is critical for making consistent parts.

Read MoreEXTRUSION: Understanding The Barrier Gap

All barrier screws are not created equal, and the barrier length and gap can be one of the reasons.

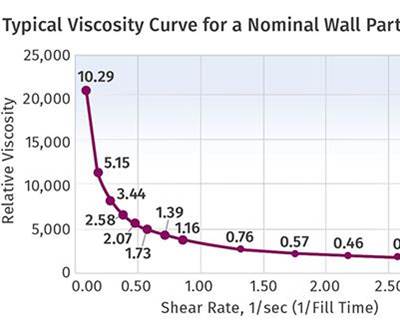

Read MoreINJECTION MOLDING: Do You Need to Profile Injection Velocity?

Look at the parts. If the answer is yes, the on-machine viscosity curve can help.

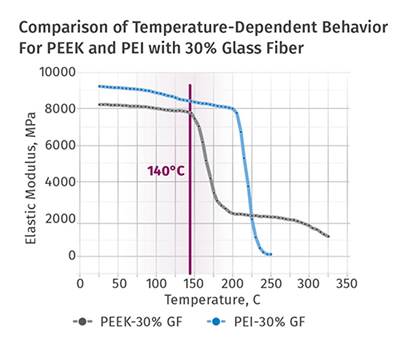

Read MoreMATERIALS: The Problems with Single-Point Data: Part 10

You can predict creep performance of a material over time at a particular temperature by examining how its modulus changes over a range of temperatures.

Read MoreTOOLING: Repairing Molds in the Press: Part 3

This is the final part of a series on tooling in the press. This column will cover repairs that can be accomplished in the press.

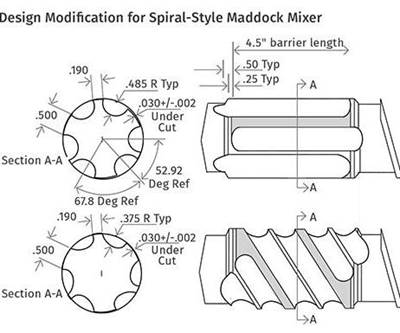

Read MoreEXTRUSION: Venerable Maddock Mixer Still an Extrusion Workhorse

Variations to this decades-old mixing section are widely used, but processors should carefully analyze these designs and not assume they will perform better.

Read More