Know-How

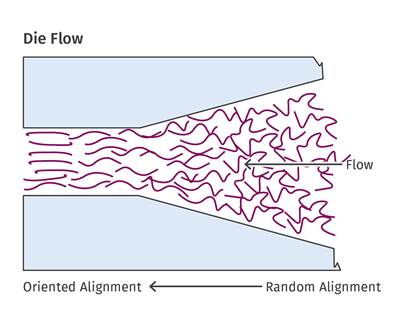

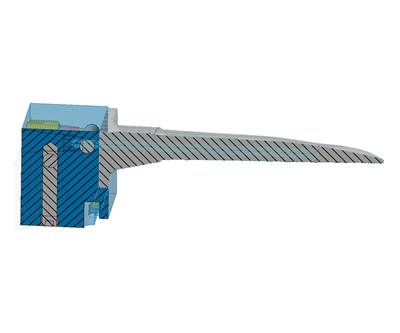

EXTRUSION: Orientation: The Good and the Bad

Depending on what you are trying to accomplish, molecular orientation can have a positive or negative impact on your part. Here’s how to control it.

Read MoreTOOLING: Let’s Get Serious About Mold Cooling: Part 2

Some creative thinking with conventional technology, like small cooling lines and bubblers, can generate big improvements in cooling and cycle times.

Read MoreINJECTION MOLDING: Purging: A to Z

Use these steps as a guide to minimize the time and money it takes to switch materials and color on your presses.

Read MoreTOOLING: Let’s Get Serious About Mold Cooling

Cooling is crucial to the molding process yet frequently overlooked. Here are some insights to consider.

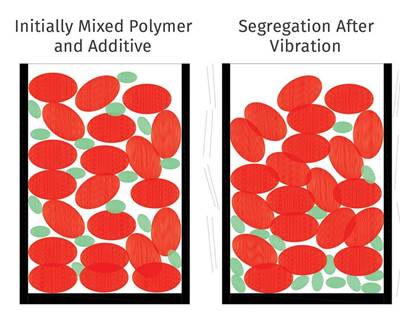

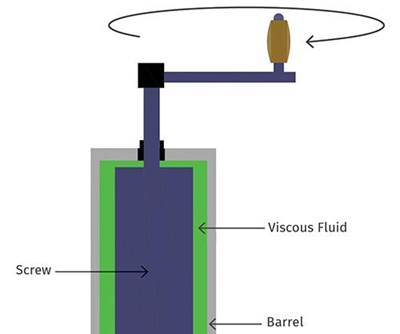

Read MoreEXTRUSION: Better Mix In Means Better Mix Out

Segregation or de-mixing of polymers and additives can be a big problem in single-screw extrusion. Here’s why it happens, and how to fix it.

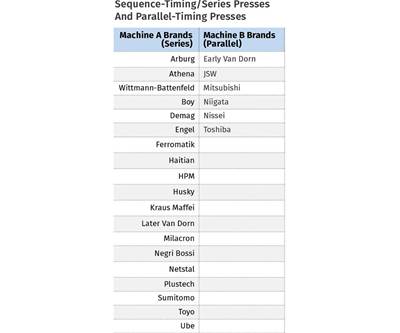

Read MoreINJECTION MOLDING: How Different Machine Types Handle Fill and Pack/Hold Times

The procedures are different between series and parallel machines. What type do you have? How can you tell? Here’s what you need to know.

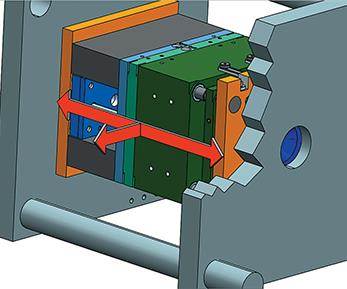

Read MoreTOOLING: The Tool’s Impact On the Molding Process

Flash, venting, cooling, gating, or sticking problems? Better to fix the tool than distort your process.

Read MoreEXTRUSION: How Slow Can You Go?

Larger screws designed for high outputs will generate a variety of problems if run too slowly. Here’s why.

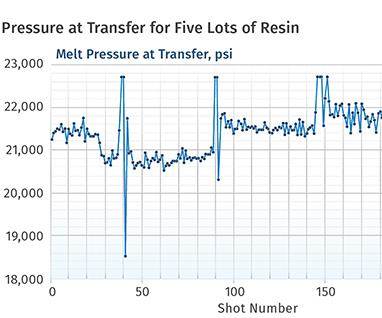

Read MoreINJECTION MOLDING: Processing Nylon…and Other Problems

As moisture content in this and other hygroscopic resins varies, so will your viscosity and process. Here’s how to deal with these issues

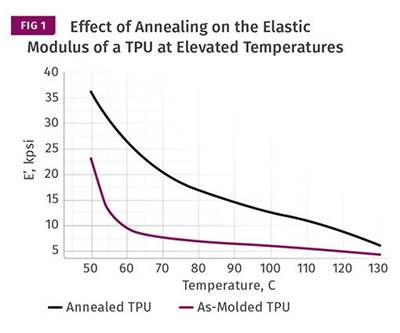

Read MoreMATERIALS: Thermoplastic Urethanes: Why Annealing Makes a Big Difference

Under the right conditions, annealing can drive TPU performance to a greater level than can be achieved at room temperature.

Read More