Know-How

Injection Molding: Put Out the Production Fire Once and for All

A deliberate approach to failure assessment, root-cause analysis, solution development, and continued monitoring is the only way to get off the treadmill of chasing the latest production problem.

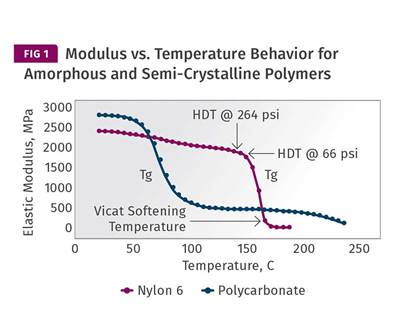

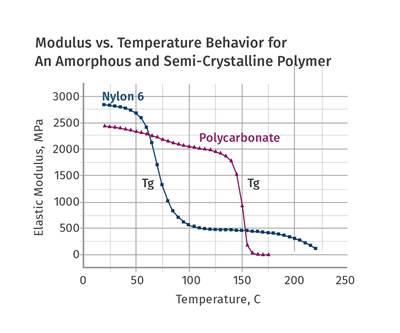

Read MoreMaterials—Cycle Time: Science vs. Rules of Thumb—Part 3

To properly calculate cycle time, you need to understand how the modulus of a polymer increases as it cools in the mold.

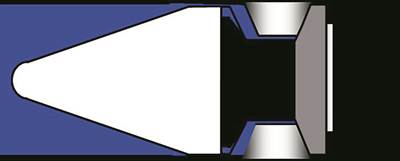

Read MoreTooling: Critical Design Considerations for Sprue Bushings

Among them are good cooling, proper orientation, solid retention, structural integrity, generous radii, and an appropriately polished bore.

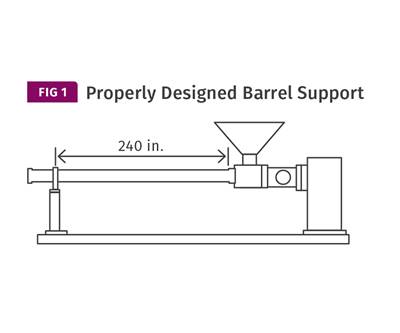

Read MoreExtrusion: The Importance of Proper Barrel Supports

Supports that allow the barrel to expand and contract easily will prevent alignment issues. Examine them periodically for proper operation, particularly if you’re experiencing excessive wear.

Read MoreInjection Molding: Time for Another Look at Non-Return Valves

First and foremost, they must seal properly, and check valves with stepped angles or radiused seats perform the best.

Read MoreMaterials: Cycle Time: Science vs. Rules of Thumb—Part 2

Understanding cooling—how a given material develops modulus as it solidifies—requires access to data that provides some insight into the relationship between modulus and temperature. Dynamic mechanical analysis is a helpful tool.

Read MoreHow to Collect and Interpret Extrusion Process Data; Part 3

In this final installment, learn how process data can be used to identify and fix extrusion issues.

Read MoreTooling: Reducing the Mass In Sprue Bushings

Important and frequently overlooked details of sprue-bushing design can improve the process and profits for an injection mold.

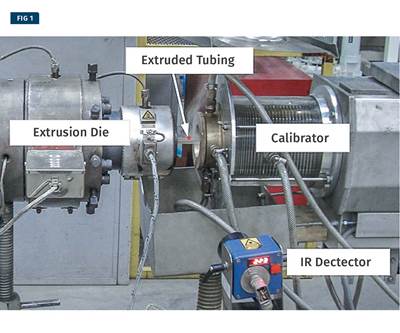

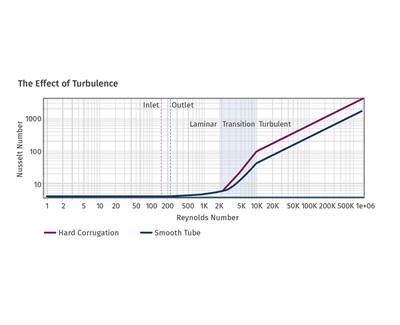

Read MoreExtrusion Cooling: It’s All About Turbulence

Regardless of what you are extruding, in order to maximize cooling you need to generate turbulence at the heat-exchange surface.

Read MoreInjection Molding: Are You Using More Than 65% Of Your Barrel Capacity?

If you are, you are inviting Murphy—as in trouble—to the party.

Read More