Know-How

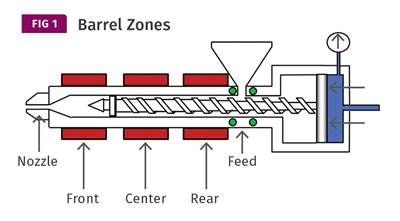

Injection Molding: How to Set Barrel Zone Temps

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

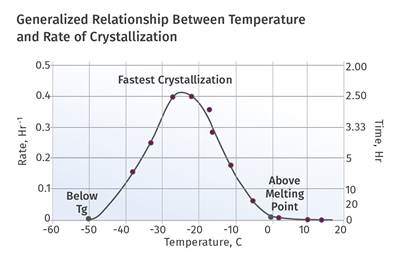

Read MoreA Processor’s Most Important Job, Part 3: Unintended Consequences

Processors are often expected to compensate for ill-advised decisions made earlier in the product-development process. In the case of shrinkage, one of the most common ‘fixes’ is to simply reduce the mold temperature.

Read MoreTooling: Tunnel Gates for Processors, Part 2

What you need to know to overcome problems out on the production floor.

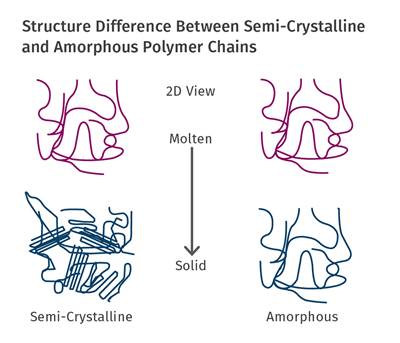

Read MoreInjection Molding: Melting Amorphous vs. Semi-Crystalline Plastics

Understanding the differences in how each melts is crucial to obtaining melt uniformity.

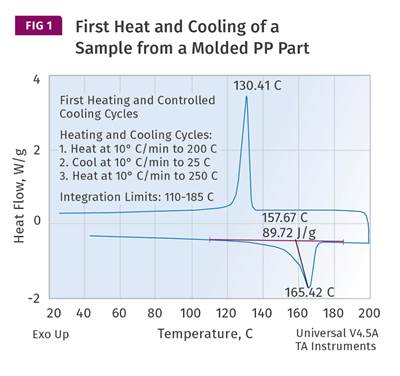

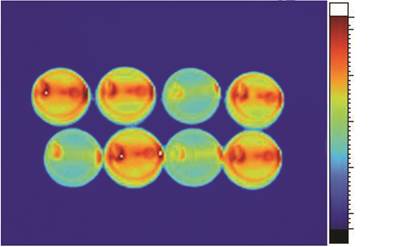

Read MoreA Processor’s Most Important Job, Part 2: Crystallinity

Process conditions help determine the difference between the maximum degree of crystallinity that can be achieved in a polymer and the degree that is present in a molded part.

Read MoreInjection Molding: Nozzle Heaters & Thermocouples: A Case of Wiring Done Wrong

Incorrect placement of wires for these components frustrates molders and costs them money to boot.

Read MoreA Processor’s Most Important Job, Part 1: Molecular Weight

Many processors don’t realize that preserving material characteristics is crucial to product success and failure. The focus here is on molecular weight.

Read MoreHow Sprue Pullers Help Prevent Molding Issues: Part 2

A vital secondary function of sprue pullers is to act as a cold well to trap solidified material left in the machine-nozzle tip.

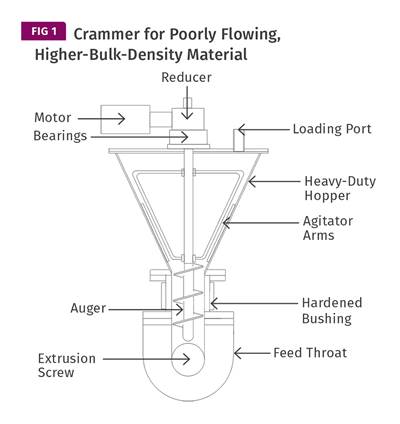

Read MoreExtrusion: How Hopper Crammers Can Help Feeding

A crammer can assist the flow of certain polymers into the extruder. But the design is not universal and very material dependent. Here’s what you need to know.

Read MoreInjection Molding: New Mold Trial—Will It Run 24/7?

Use this nine-step process to make sure you’ll be making good parts after a successful trial. But even then, be prepared for some hiccups.

Read More